The marine, automotive, and construction industries all use rubber molding. A fluoropolymer elastomer is added to Viton™ rubber, a specialty synthetic rubber. Viton™ rubber is particularly resilient in applications subjected to potent chemicals because of this combination. In addition, Viton™ performs well even in extreme weather or high temperatures, which makes it ideal for molding applications when the circumstances aren’t optimal. Although Viton™ rubber is more expensive than most rubber parts, it is also more robust and will probably last much longer than any other type of rubber grade used for molding. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

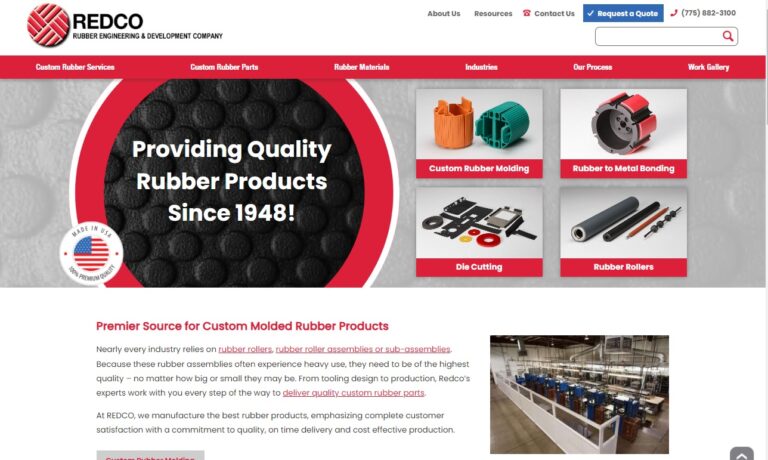

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

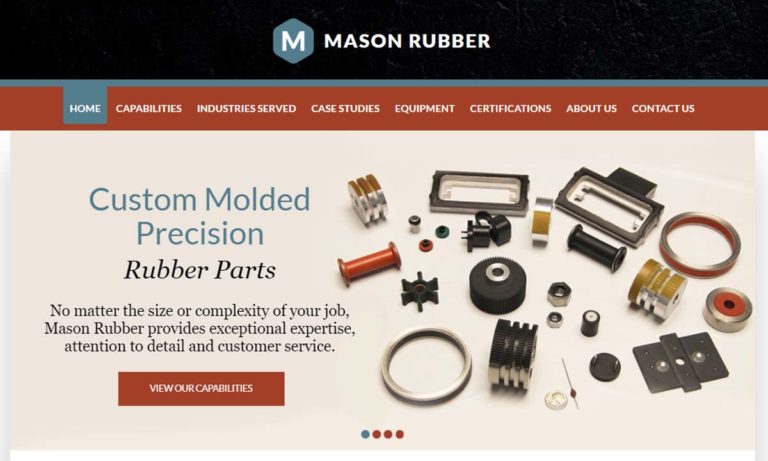

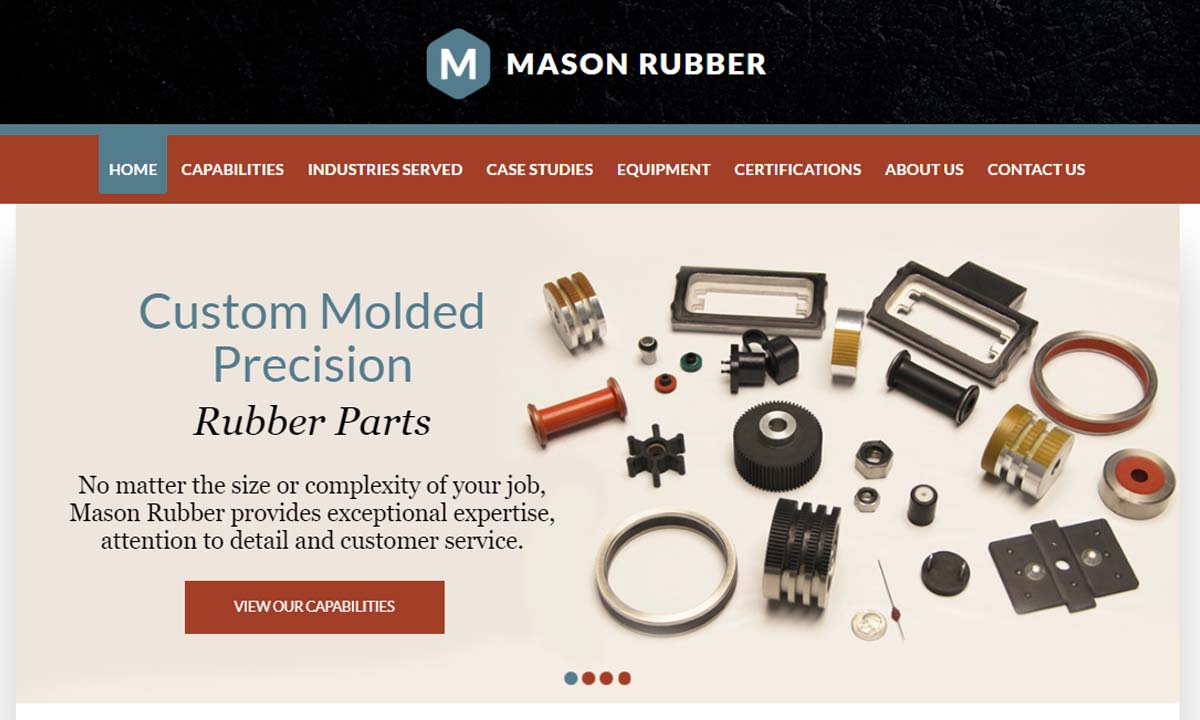

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

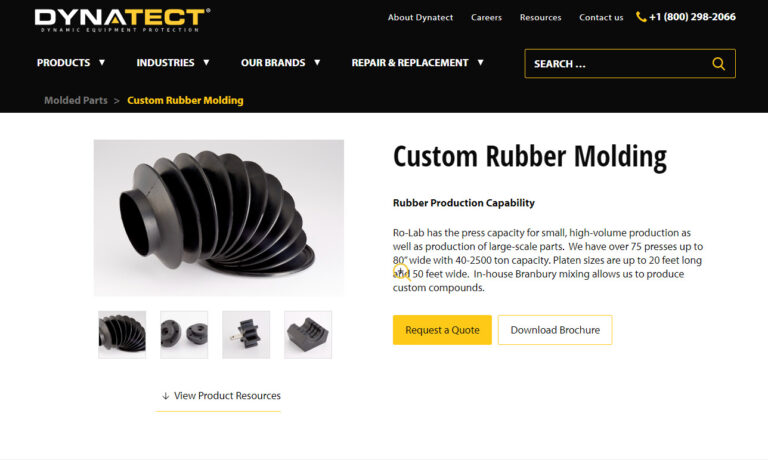

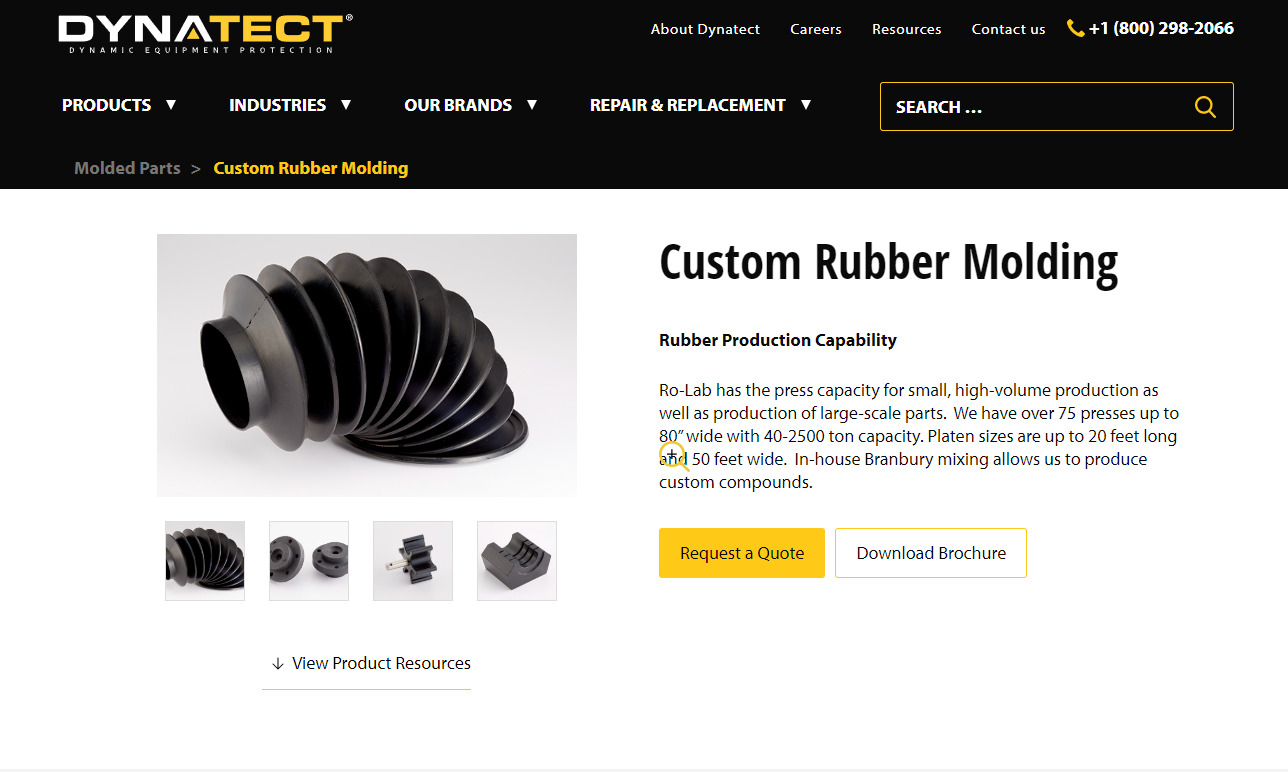

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Viton Rubber Molding Companies

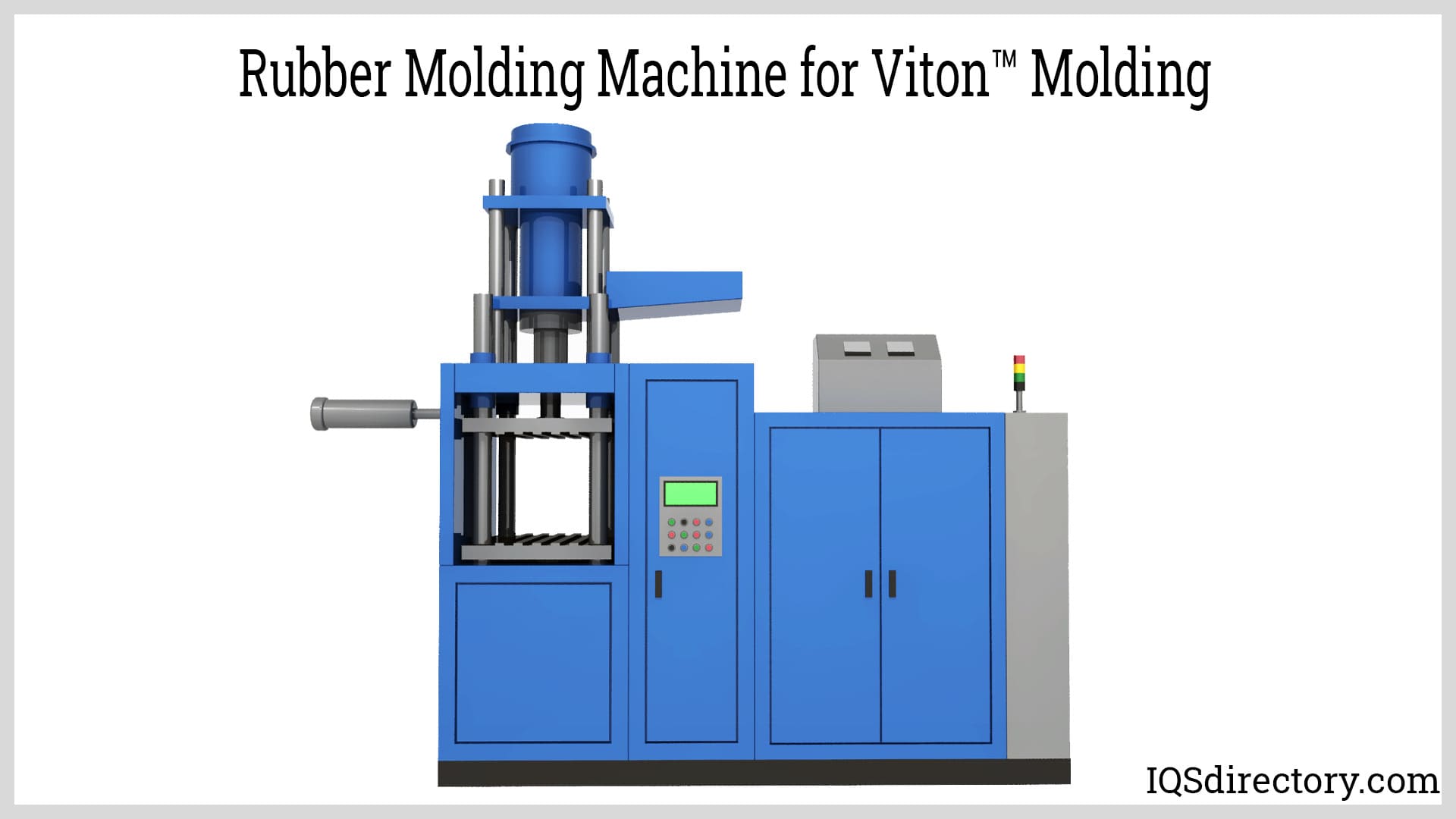

Processes for Molding Viton™ Rubber

Viton™ rubber can be produced using either compression molding or injection molding. In the molding technique known as compression molding, a charge is squeezed to conform to the shape of a mold that has a bottom and upper half. Multiple components that operate as a single mechanism when compression is applied may make up a part. A cavity that defines the required shape is left between the mold's two parts when they come together. Parts are joined at the shape's broadest cross-section to make it easier for the product to be ejected after curing. For thermosetting materials, it is the most affordable molding technique.

Flash molds are the most popular compression molds, including positive, landing positive, and semi-positive molds. Bulk and sheet compression molding are the two forms, and fillers, catalysts, stabilizers, colors, and fiber reinforcers are typically used in bulk molding. In any case, the advantages of compression molding thermoset polymers include exceptionally high strength, lightweight products featuring corrosion resistance. An uncured rubber form roughly resembles the product's shape and is placed into an accurate mold during the compression molding process, where it is squeezed between the plates. This pressure squeezes out the extra rubber and air, and the rubber is then heated to aid in curing.

The heated rubber is forced through a machine barrel and out of a nozzle during the injection molding, after which it is injected into a mold. It forms the appropriate rubber part when it cools by filling the mold's voids. Before the rubber is taken out of the mold and used for packing, it is given time to cure.

Viton™ Rubber Characteristics

Viton™ is distinguished from other non-fluorinated elastomers by its:

- Resistance to degradation by a wider range of fluids and chemicals.

- Excellent resistance to lubricants, oils, fuels, and most mineral acids.

- Extremely low permeability to various substances, with an especially strong performance in gasoline with added oxygen.

- Resistance to solvents that dissolve other rubbers, such as aliphatic, aromatic hydrocarbons.

- Extremely strong compression set resistance, even at high temperatures.

- Exceptionally strong resistance to weather, sunlight, and atmospheric oxidation.

- Good electrical properties in low voltage, low-frequency applications; it provides excellent resistance to fungi and mold.

- Low flammability: it is naturally more flammable-resistant than other, non-fluorinated hydrocarbon rubbers.

Viton™ Rubber Molding in Engines

The O-rings of a car's fuel injectors frequently have Viton™ rubber molding. Gasoline compression is maintained thanks to the material's flawless seal, and despite being continuously exposed to fuel while the engine is operating, Viton™ rubber does not degrade. Because engines generate a lot of heat while operating, Viton™ rubber is ideal for withstanding the conditions beneath a car's hood. The same idea holds for engines found in both boats and construction machinery. Using Viton™ rubber molding reduces deterioration that could result in leaks or engine problems because boats are particularly susceptible to rubber disintegration if used in saltwater.

Advantages of Viton™ Molding Rubber

Viton™ molding rubber is better able to endure high temperatures while preserving excellent mechanical qualities than most elastomers. The resistance to oil and chemicals is unaffected by high temperatures. When subjected to intermittent exposures up to 316°C or laboratory air oven aging up to 204°C, Viton™ compound materials maintain a significant amount of their elasticity. More than any other non-fluorinated elastomer, Viton™ grades also withstand deterioration from a greater range of chemicals and fluids, including oils, fuels, lubricants, and most mineral acids. It offers the best fluid resistance of any commercial rubber, to put it simply. Viton™ is recognized to function remarkably well in oxygenated automobile fuels because of its low permeability to various chemicals. Viton™ has more robust qualities than that, though. Since they exhibit strong compression resistance even at temperatures that would lead other non-fluorinated elastomers to become brittle, it has a high level of resistance to fungus, mold, sunlight, climate change, and air oxidation.

Choosing the Proper Viton™ Rubber Molding Company

To make sure you have the most productive outcome when selecting a Viton™ rubber molding company, it is important to compare at least 5 companies using our Viton™ rubber molding directory. Each Viton™ rubber molding company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each Viton™ rubber molding company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Viton™ rubber molding companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services