This form of synthetic rubber is useful because it is resistant to oil, fuel and other chemicals due to the nitrile within the polymer. The higher the nitrile levels, the higher the rubber’s resistance to chemicals will be. However, raising the nitrile level will lower the flexibility of the material. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

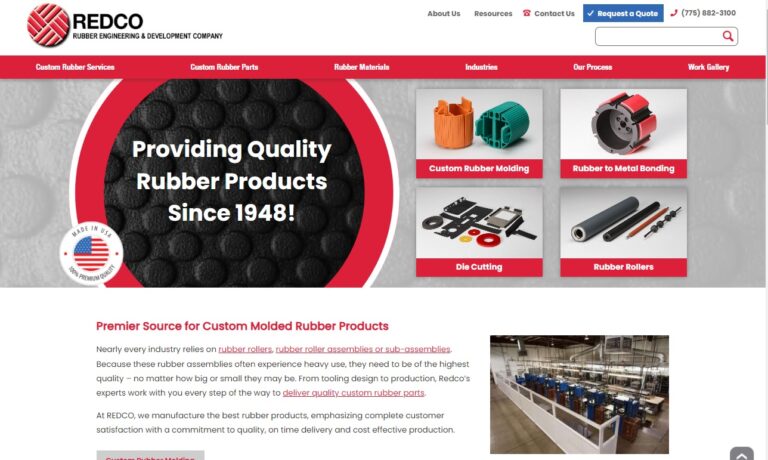

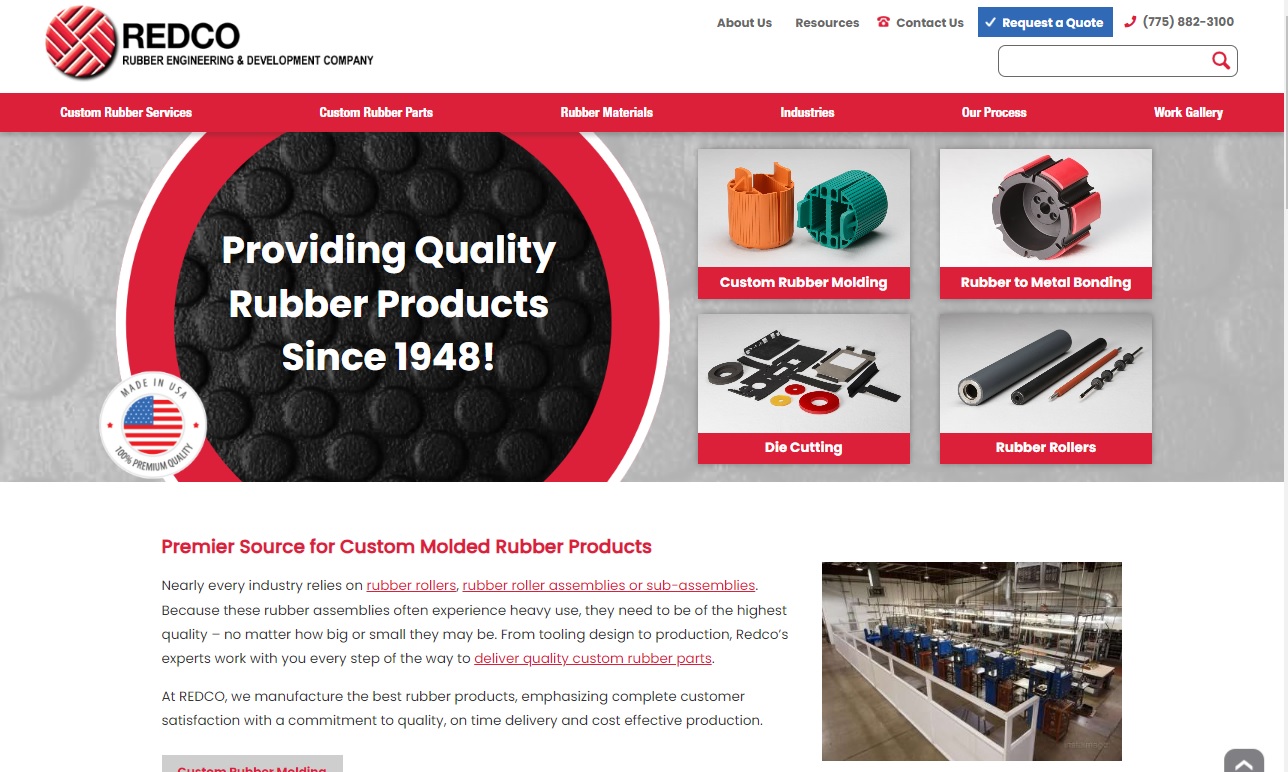

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

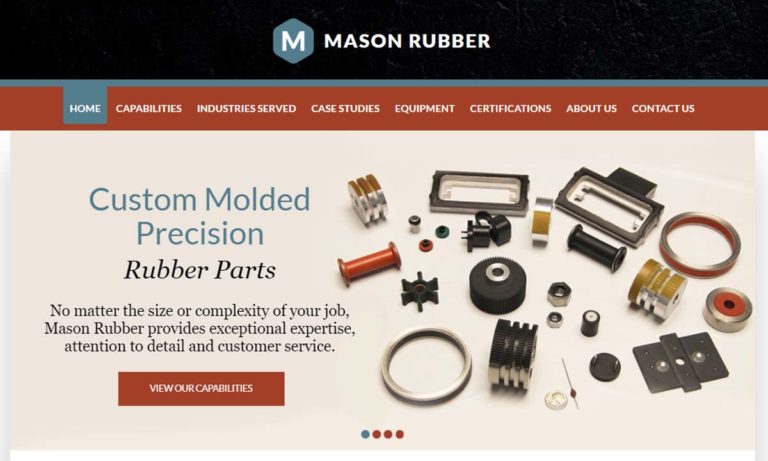

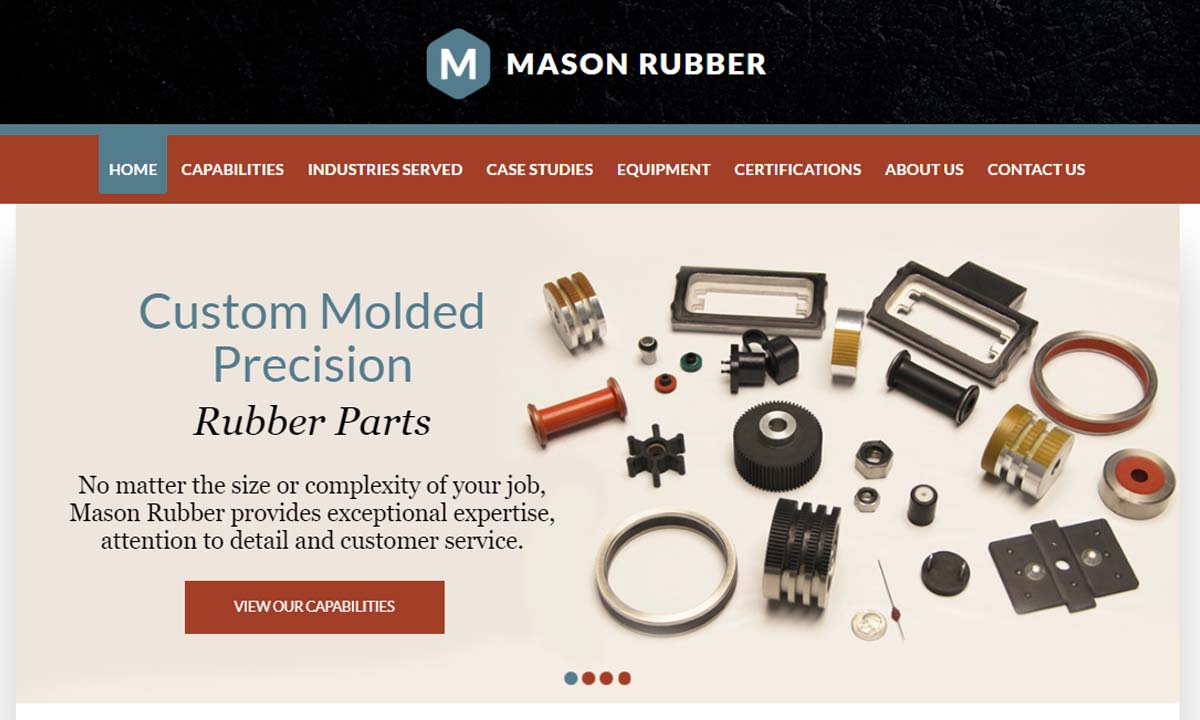

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

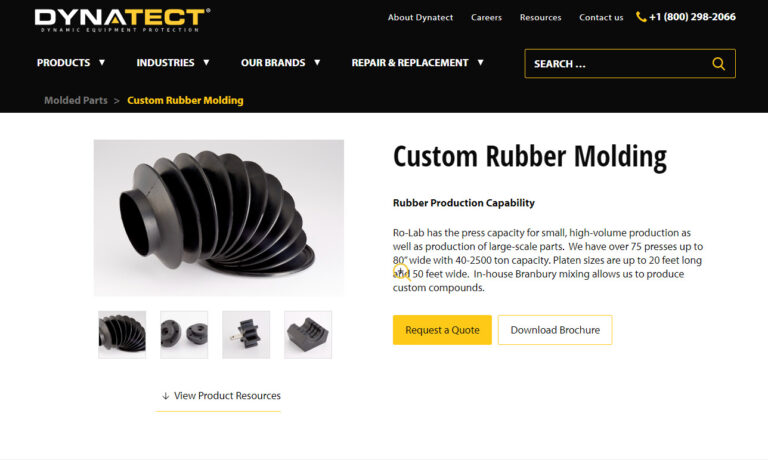

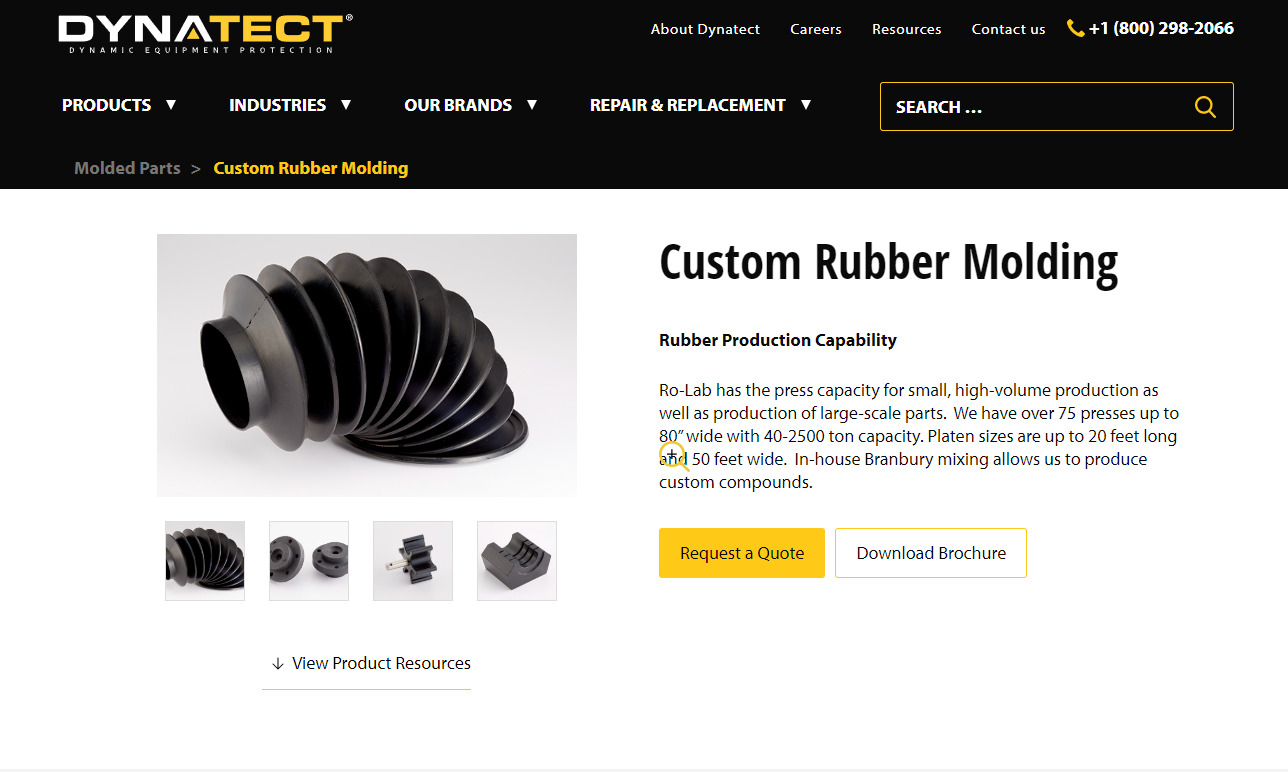

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Nitrile Rubber Molding Companies

Nitrile rubber molding can be useful in many applications if the appropriate balance of chemical resistance and flexibility can be maintained. Nitrile rubber molding is widely used in the automotive and aeronautical industries to make hoses, seals, and rubber grommets since ordinary rubber would only break down when exposed to fuel during regular use. Nitrile rubber has the ability to withstand temperatures from -40 degrees Celsius to 180 degrees Celsius, which makes it the ideal material for many aeronautical applications.

People working in nuclear and scientific research use gloves made from nitrile because they offer such good protection from harmful chemicals and dangerous high temperatures.

Nitrile rubber can be made using a hot or cold process. In the hot process, the necessary chemicals are mixed in a tank that is set to 30 or 40 degrees Celsius. After being allowed to react for a few hours, the substance receives additives to stop the reaction process.

After being filtered and stabilized, the substance is washed and dried. At this point, it is ready to be molded into a product using either a compression or injection molding process.

The cold process takes place in a similar polymerization tank that is such to a much cooler temperature. In these conditions, the polymers will not branch as much, so the end result will be a product that looks notably different from nitrile rubber made with heat.

Nitrile rubber is often manufactured in large quantities and then molded into a product at another facility. Some nitrile rubber producers also manufacture products, but most sell their nitrile rubber to product manufacturers who mold the rubber in their own plant to form something that meets their specifications.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services