Polychloroprene was originally known as duprene, and it was the first mass-produced synthetic rubber in existence. Since its invention in the 1930s, Neoprene remains in wide use throughout industry and commerce. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

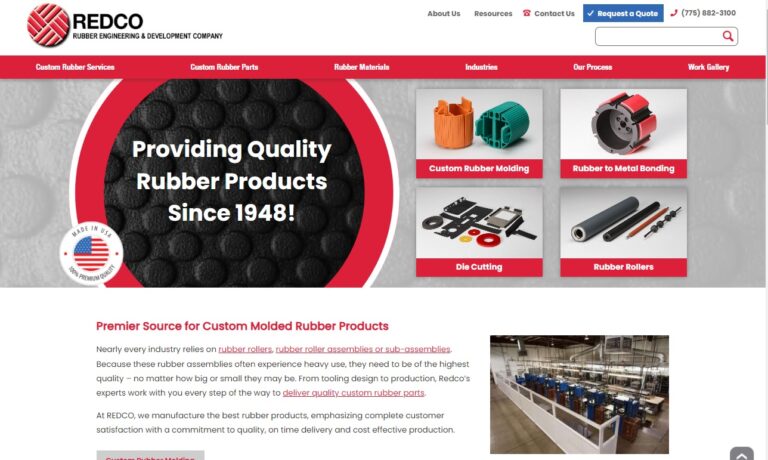

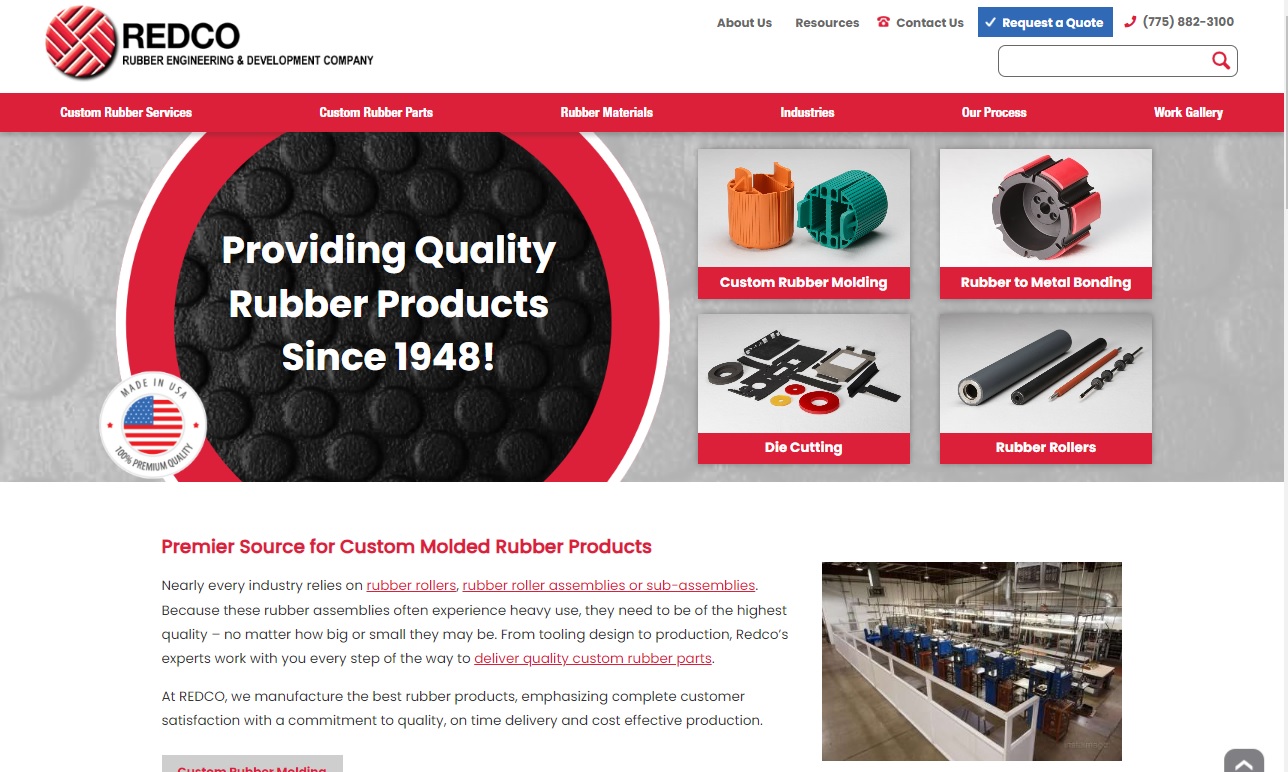

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

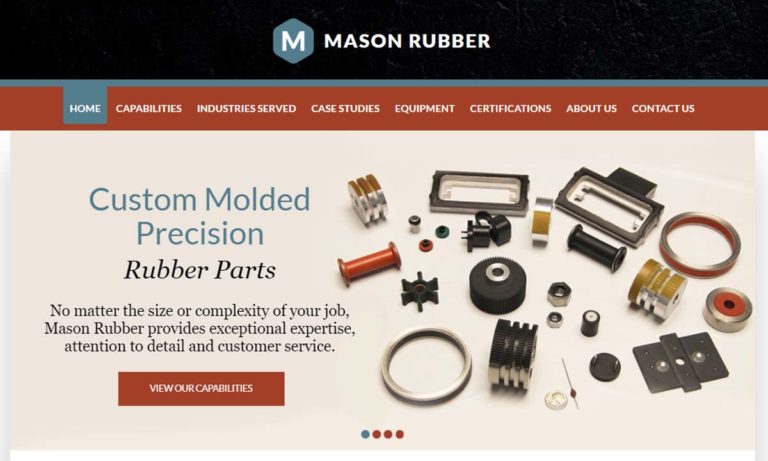

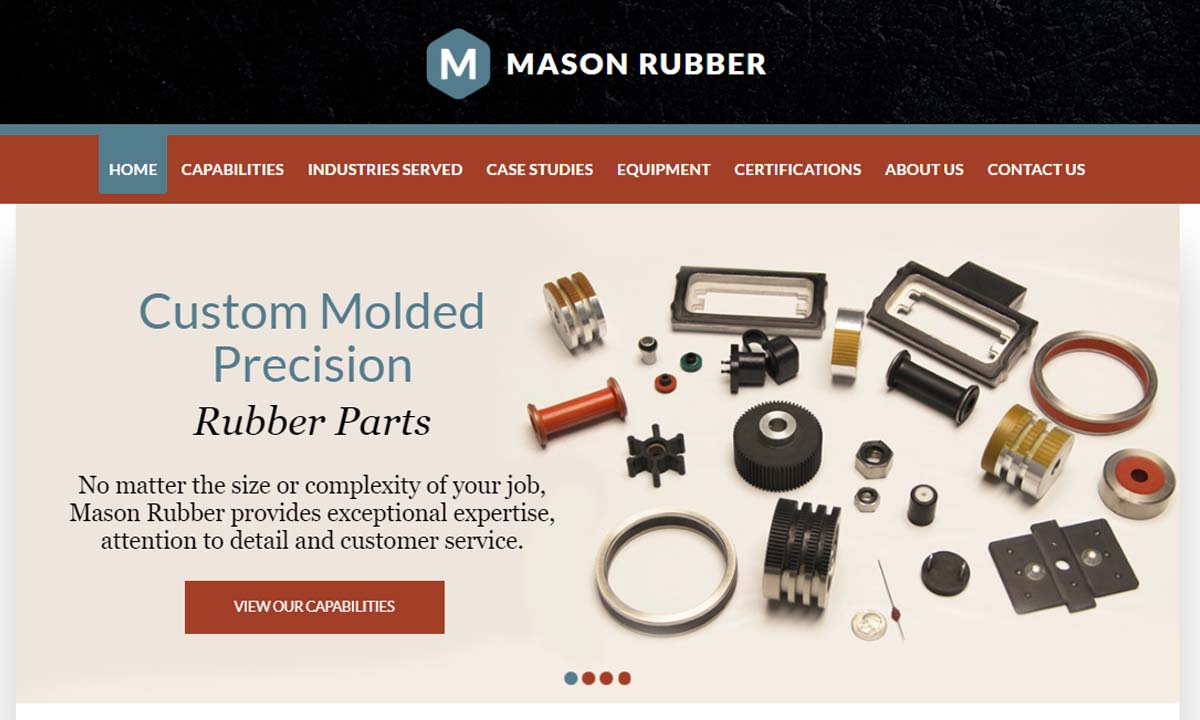

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

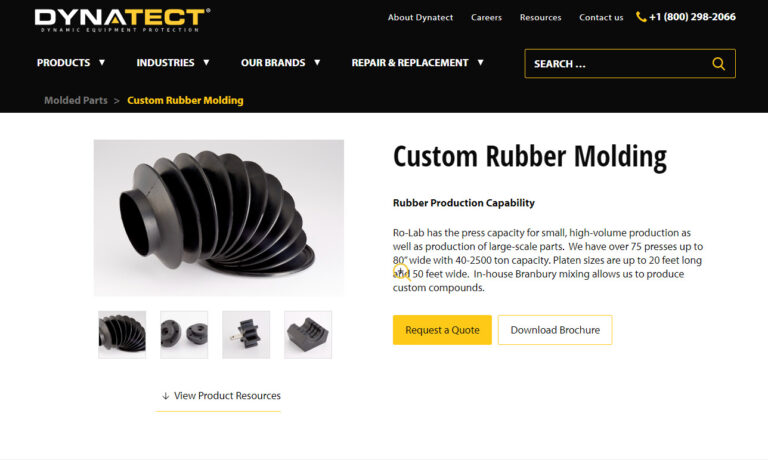

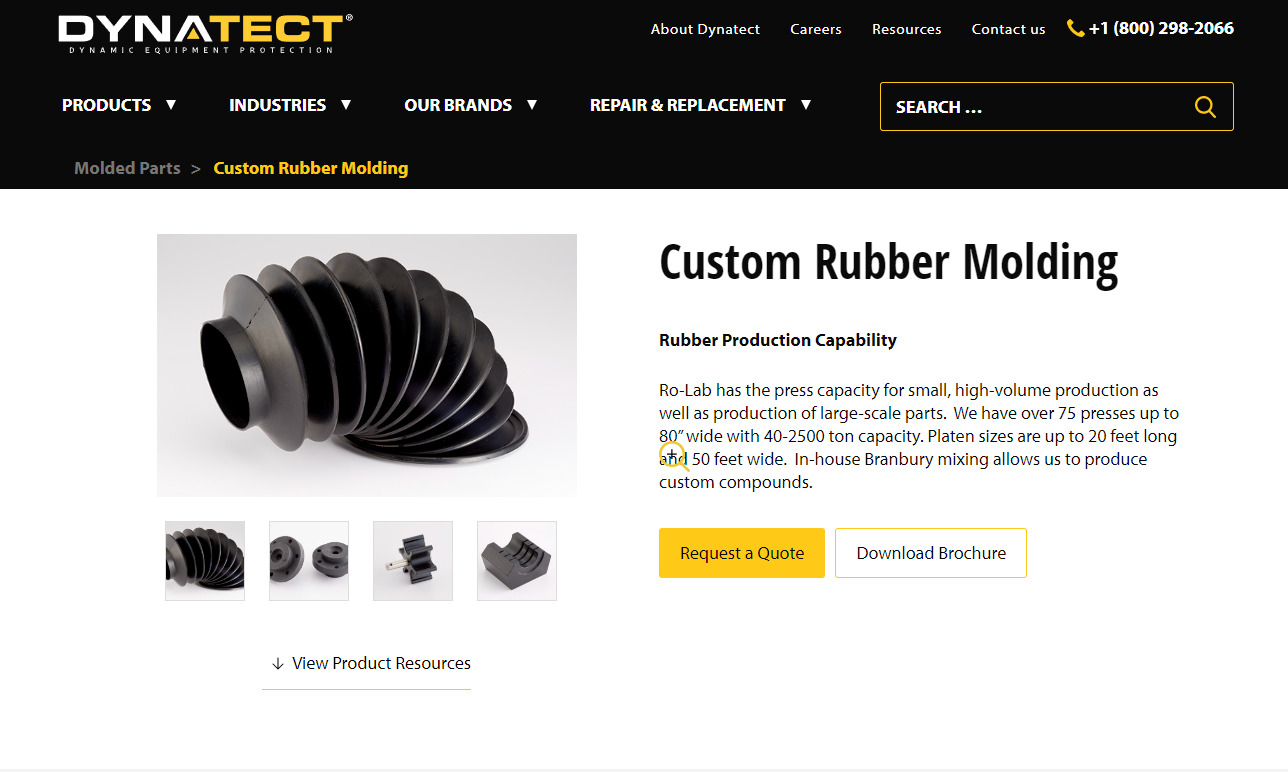

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Neoprene Rubber Molding Companies

Neoprene has become valued for its ability to maintain flexibility even when exposed to a wide range of temperatures, and its exceptional durability, weather resistance and chemical inertness distinguish it from other synthetic rubber varieties.

Neoprene rubber molding is used in the electronics industry to create protective gear for sensitive or fragile electronic devices. This type of rubber molding is also an excellent option for more demanding applications in the automotive industry; gaskets, hoses, and timing belts are often made using Neoprene.

Industrial manufacturing equipment like conveyor belts, mounting pads and other vibration control products can be made using the neoprene rubber molding process, and Neoprene sports and recreation equipment like saddle pads, cinches, ankle guards, wetsuits and fly fishing waders perform well even in extreme weather conditions.

Neoprene also boasts ozone and UV ray resistance, high flame resistance and excellent buoyancy. Neoprene is created in dry, liquid and foam grades to accommodate the extensive variety of applications for which it is used. Neoprene is formed by polymerizing chloroprene, which is the joining of individual chloroprene molecules into a long chain. Once a stock of raw Neoprene has been produced, the stock can be processed into usable products. As is true for most other synthetic and natural rubber products, Neoprene molding can be processed by any one of many rubber processing methods. In the extrusion process, a collection of raw neoprene is fed into a conveyance channel where it is heated to a molten state.

The molten Neoprene is then forced through a die, which is a tool that is specially designed to give shape to raw materials. When the Neoprene emerges on the other side of the die, it cools and hardens and is ready to be shipped.

Neoprene can also be injection molded; injection molding allows for the fabrication of more complicated shapes than extrusion. Instead of a die, injection molding makes use of a mold cavity, which is a hollow space into which molten Neoprene is injected.

The Neoprene forms to the contours of the cavity, after which it is ejected, cools, hardens and is ready for shipment or additional processing. Other methods like compression molding and cell casting are also possibilities.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services