There are three standard rubber molding styles: compression, transfer, and injection. Rubber components are formed into practical items via the process of rubber molding. The tools that enable this technique are rubber molders. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

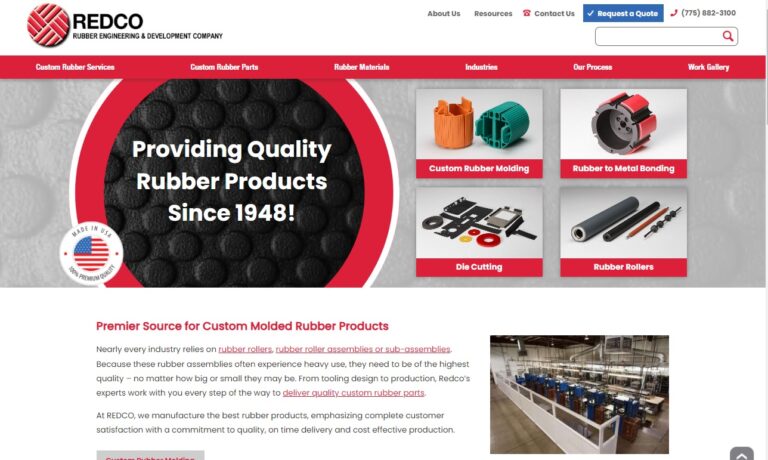

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

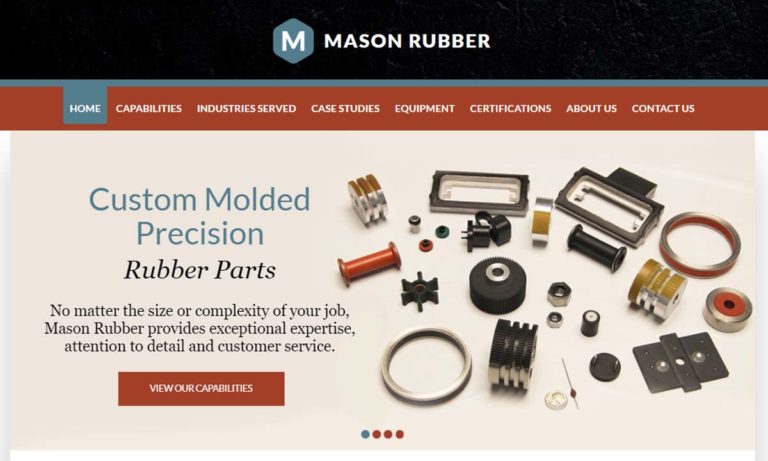

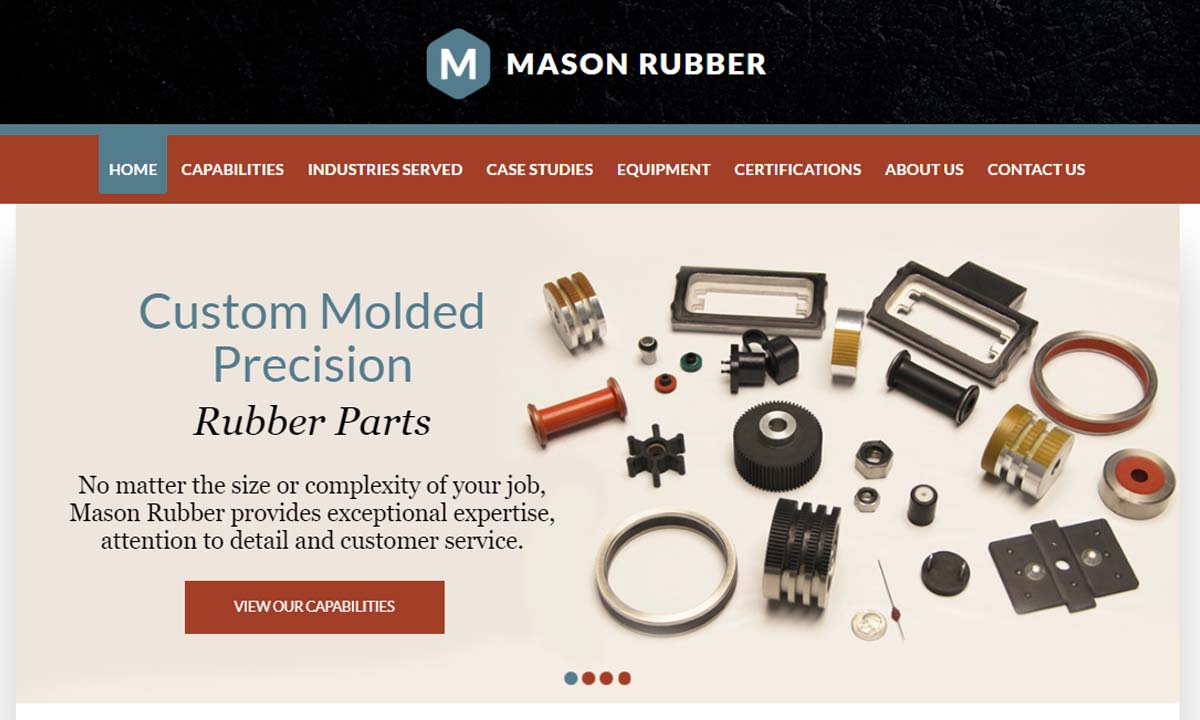

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

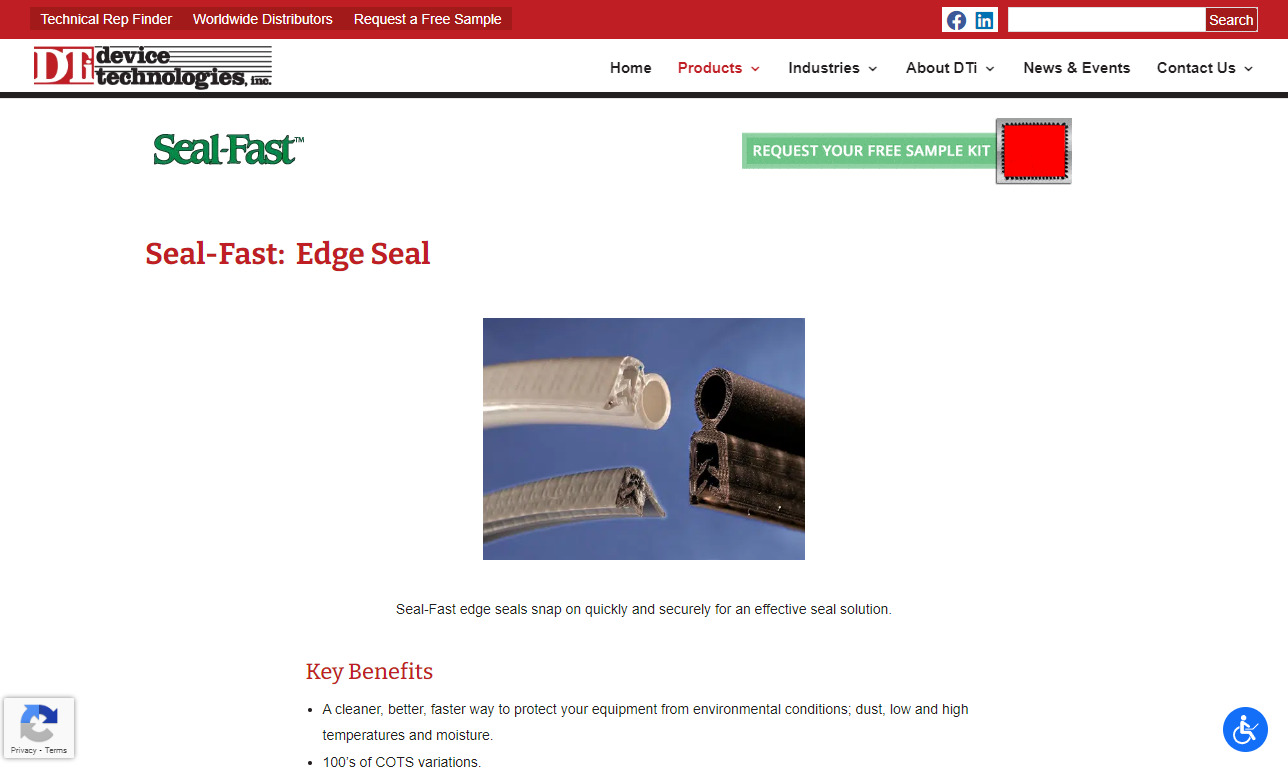

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

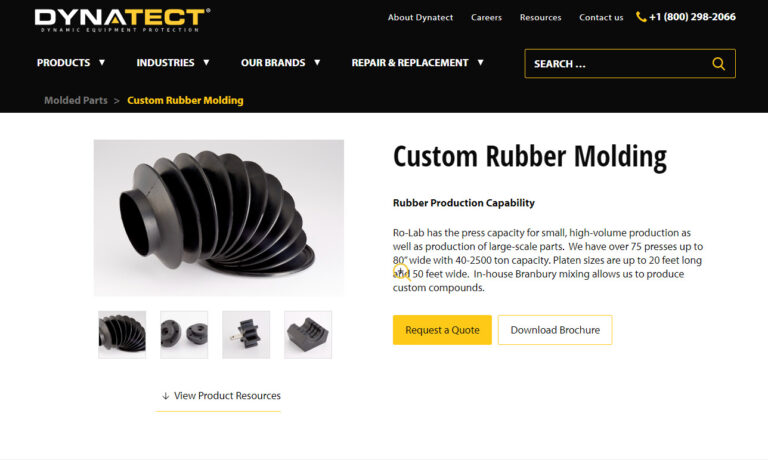

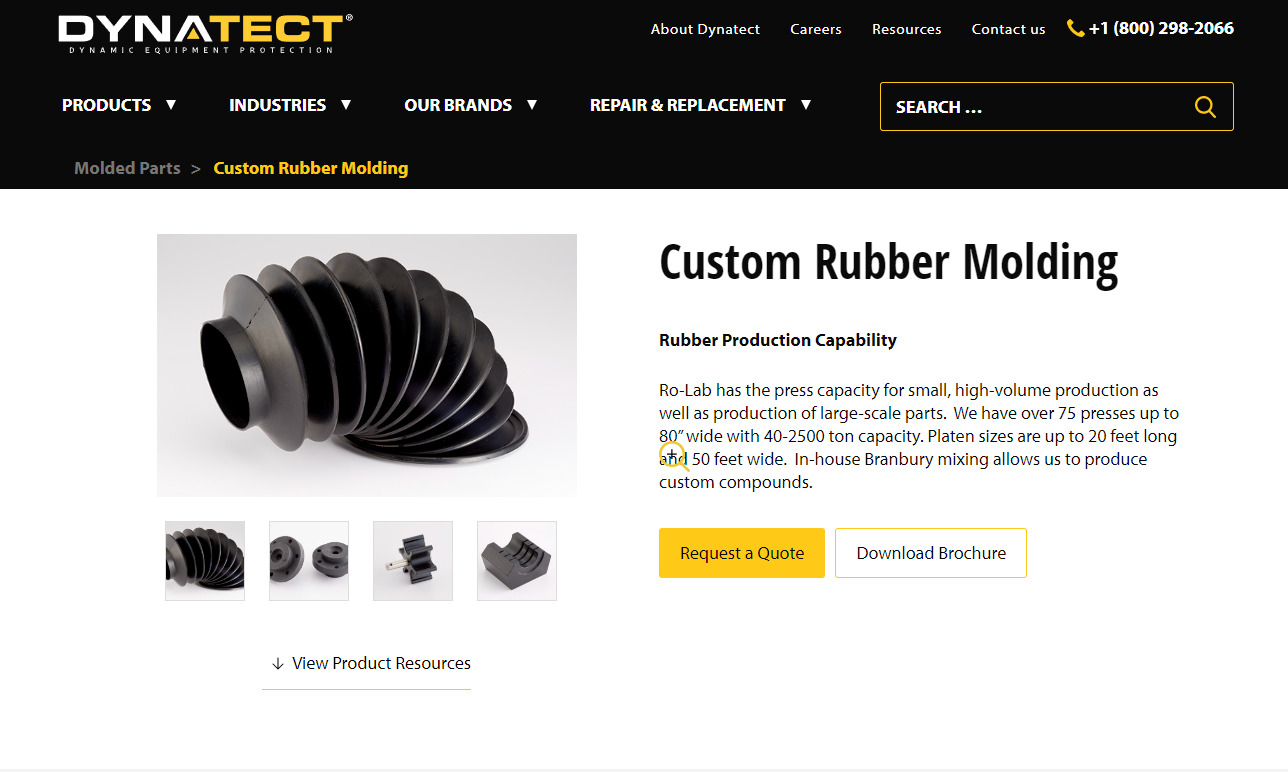

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Molder Companies

Rubber Molded Products

Molded rubber goods are used in almost every sector. Machine-related manufacturing processes frequently have to deal with vibration problems brought on by moving parts. For example, machinery that vibrates is frequently secured using rubber washers or bushings that absorb vibration and stop excessive movement to safeguard workers, other machinery, and the vibrating equipment itself. Rubber molders make these parts. Rubber grommets are another well-liked item made of rubber and are employed in commercial, industrial, and residential settings. A rubber grommet is a rubber form that fits around a hole in a surface; it can shield wires or other gear from the elements as they pass through the hole.

Rubber Molders

Most rubber molders are outfitted to handle applications requiring specialized rubber molding. Custom rubber molders can design anything and produce it right away. However, customized designs are preferable for some businesses that need distinctive designs for their requirements and new items. In addition, the procedure runs faster when bespoke rubber molders are used. Therefore, customers can save time and money on high-volume rubber runs by choosing the best custom rubber molder.

Considerations When Selecting a Rubber Molder

Modern rubber molding equipment has several automation features that drive down the price of custom molding even further. Precision, tight tolerance items can be produced by using a material like liquid silicone rubber. Rubber molding enables the production of goods with a wide range of textures and finishes.

Applications of Rubber Molding

Molded rubber goods are now widely used as crucial assembly components in various commercial applications. Rubber molding contributes to various items in the market today, from bespoke mold-making and industrial roller production equipment to gaskets, grommets, seals, and parts in medical equipment, home goods, consumer appliances, and more.

The Benefits of Molding Rubber

In some circumstances, molding has significant advantages over other rubber product manufacturing techniques. While this procedure may take longer to produce parts than, say, rubber extrusion, it does allow for the creation of a wide range of intricate parts. Molding also provides flexibility. It uses numerous rubber-based raw material formulas, enabling the creation of goods with various required characteristics, such as durability or high heat resistance. Modern rubber molding facilities can swiftly and effectively make large quantities of customized goods. Customers who use a brand's exclusive rubber compound can, for instance, order big production runs or design prototype goods for marketing purposes.

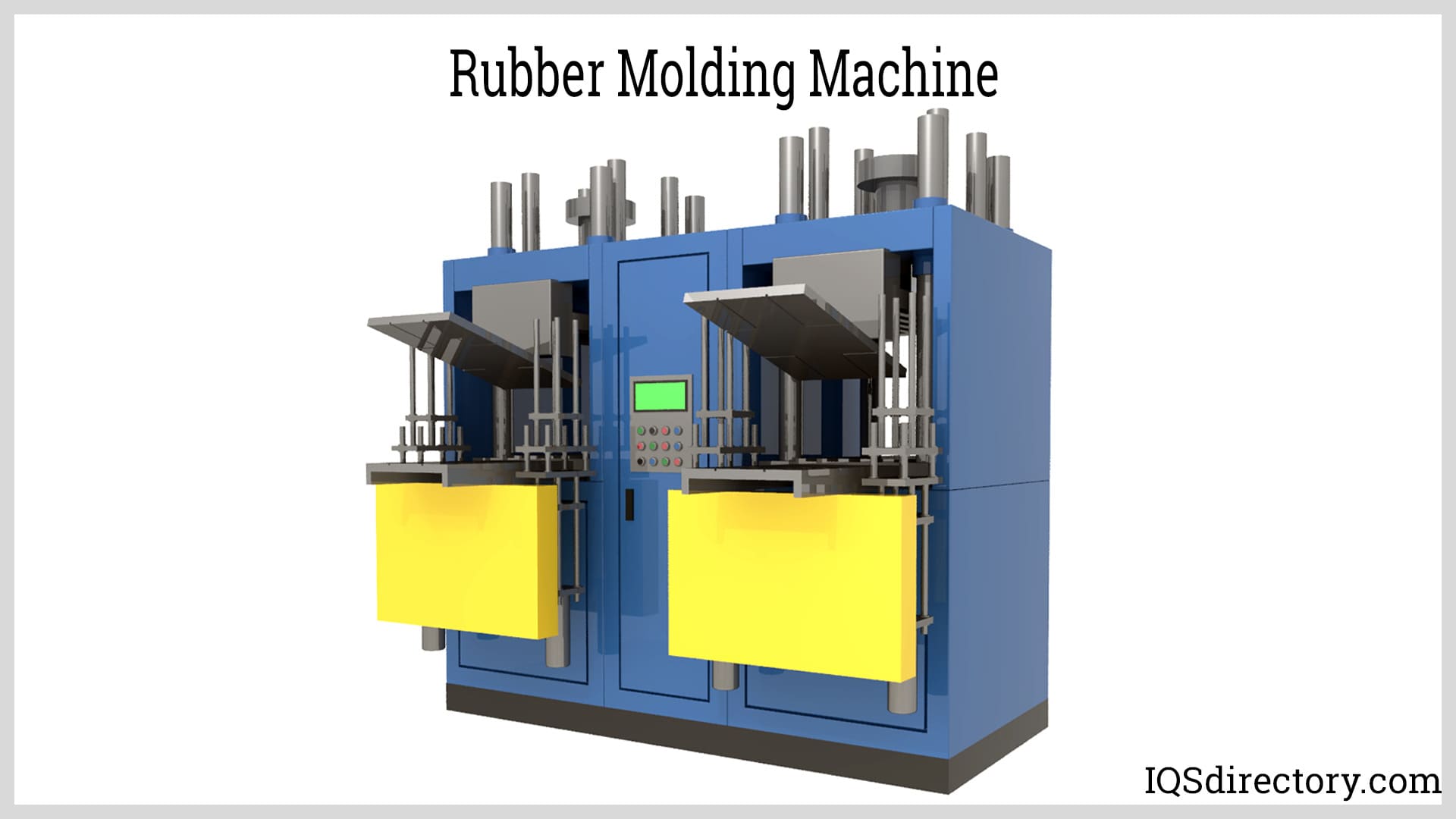

Rubber Molding Processes

Injection Molding

It is currently dominating the commercial market. During large-scale production runs, it often supplies inexpensive components. For example, a maker of rubber injection molding sets up a production line to turn solid rubber or synthetic rubber stock into molten material that is injected into a cavity in a terminal mold. Manufacturers typically use quick-moving automated technology to automate this operation. Heat and pressure working together help the maker fill molds uniformly. A rubber product forms into the required shape while cooling. This workpiece is then removed from the mold, albeit it may need to be further finished before being used in an assembly (or not).

Compression Molding

Popularity has grown among manufacturers of low-tolerance rubber or synthetic rubber parts thanks to this technology. The stock is manufactured into the required shape and weight before being placed into a mold chamber—the heavy compression mold's closure aids in shaping the prepared material into the required shape. The producer warms molds to certain temperatures and permits them to remain closed for a specified time to maximize the creation of finished goods.

Molding by Liquid Injection

Producers use liquid stock as the first raw material, such as liquid silicone rubber. The equipment used to carry out this procedure typically consists of a metering pump to help regulate and manage the silicone flow. After the initial metered discharge, the manufacturer mixes the liquid silicone with other pertinent components. The slurry is then injected into a mold using a nozzle. The maker secures the mold and then applies a specified quantity of heat and pressure to the mold to produce a product. Since the maker can start the molding process without first converting the solid stock to a liquid condition, liquid injection molding could speed up the production process. This method also produces products that require relatively little finishing.

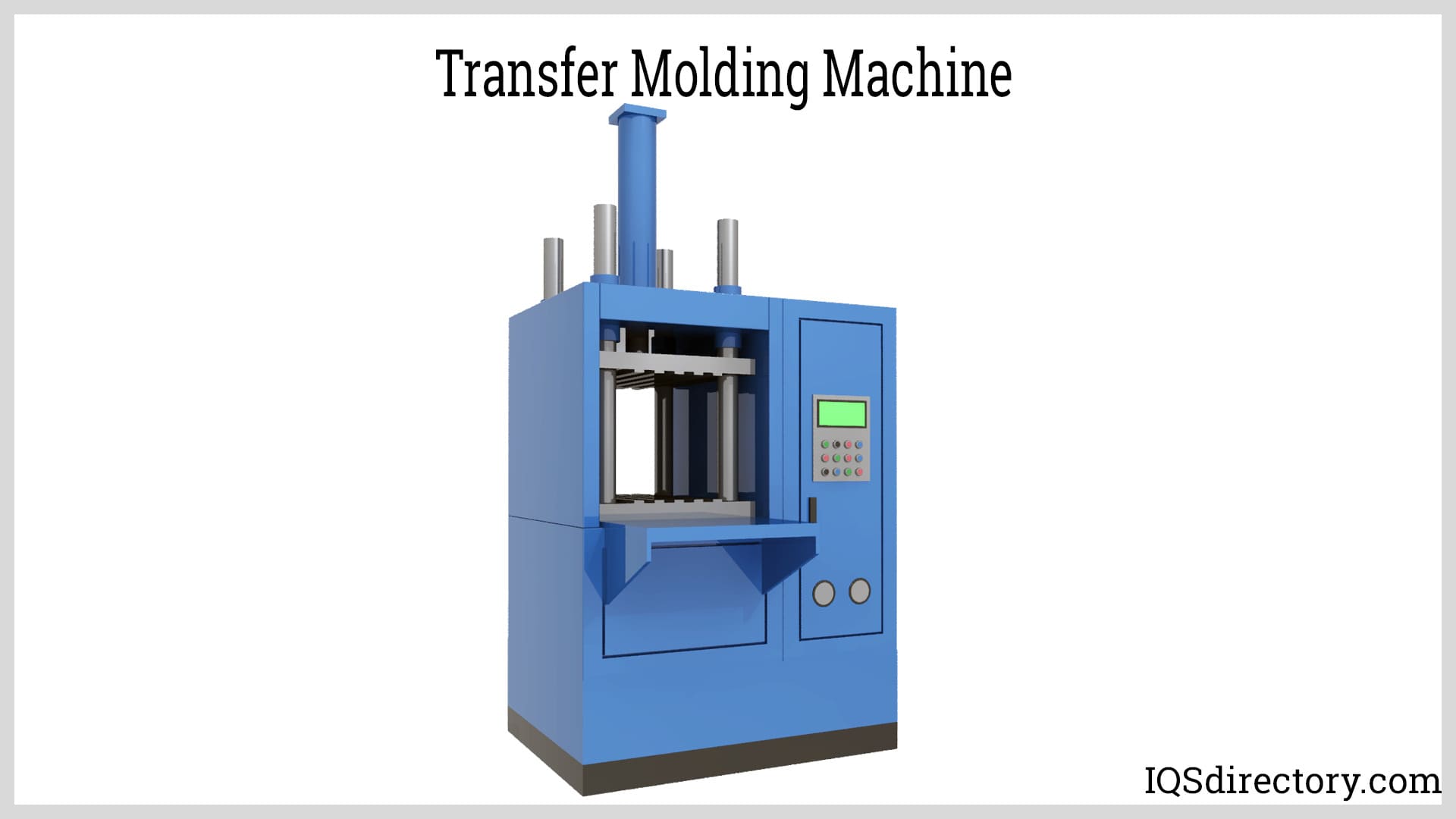

Transfer Molding

Transfer molding enables the production of precision-molded rubber components as well as rubber products that are attached to metal surfaces. The producer uses premade rubber in a certain weight, similar to compression molding. However, instead of using an open mold to place this material, the producer uses a cavity above the mold called a "pot" and a heavy mechanical component called a "ram" to press the preform into the mold through a runner and gate system as it melts when heat and pressure are applied. The ram is fixed over the mold for a predetermined amount of time.

Choosing the Proper Rubber Molder Company

To make sure you have the most productive outcome when selecting a rubber molder, it is important to compare at least 5 companies using our rubber molder directory. Each rubber molder company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each rubber molder company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber molder companies with the same quote.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services