A washer is a flat, spherical piece of hardware with a hole in the center that is frequently used to increase tension between a screw or nut and a surface. One such piece of hardware that was created from rubber is a washer. A rubber washer is most frequently employed in situations where a tight seal, with some give in the washer, and exposure to liquids like water or humidity are necessary. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

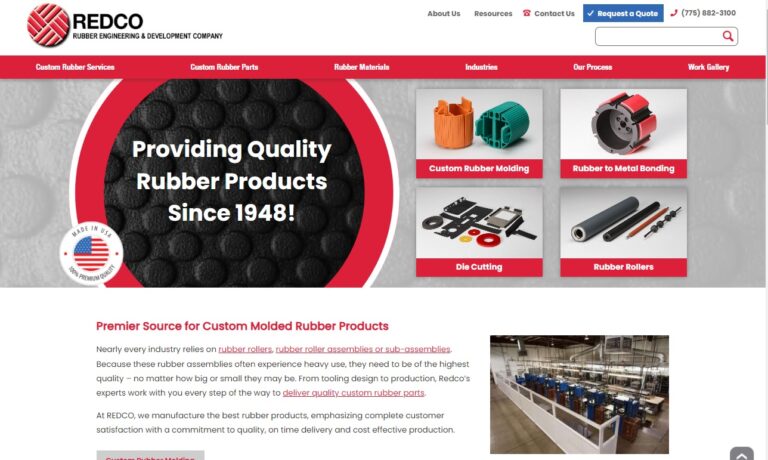

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

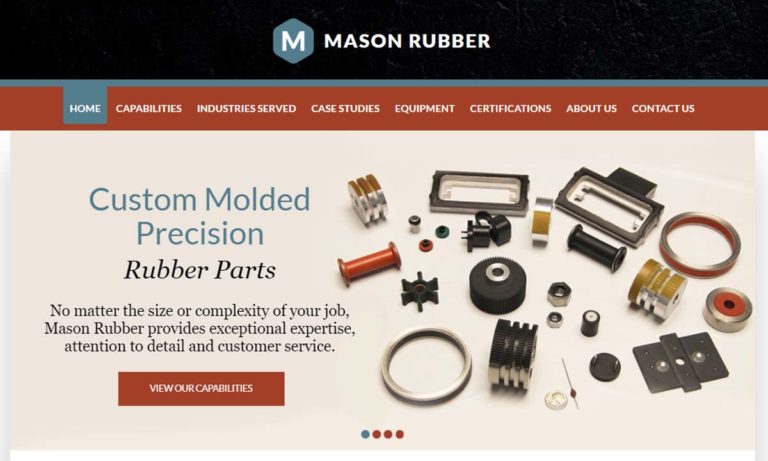

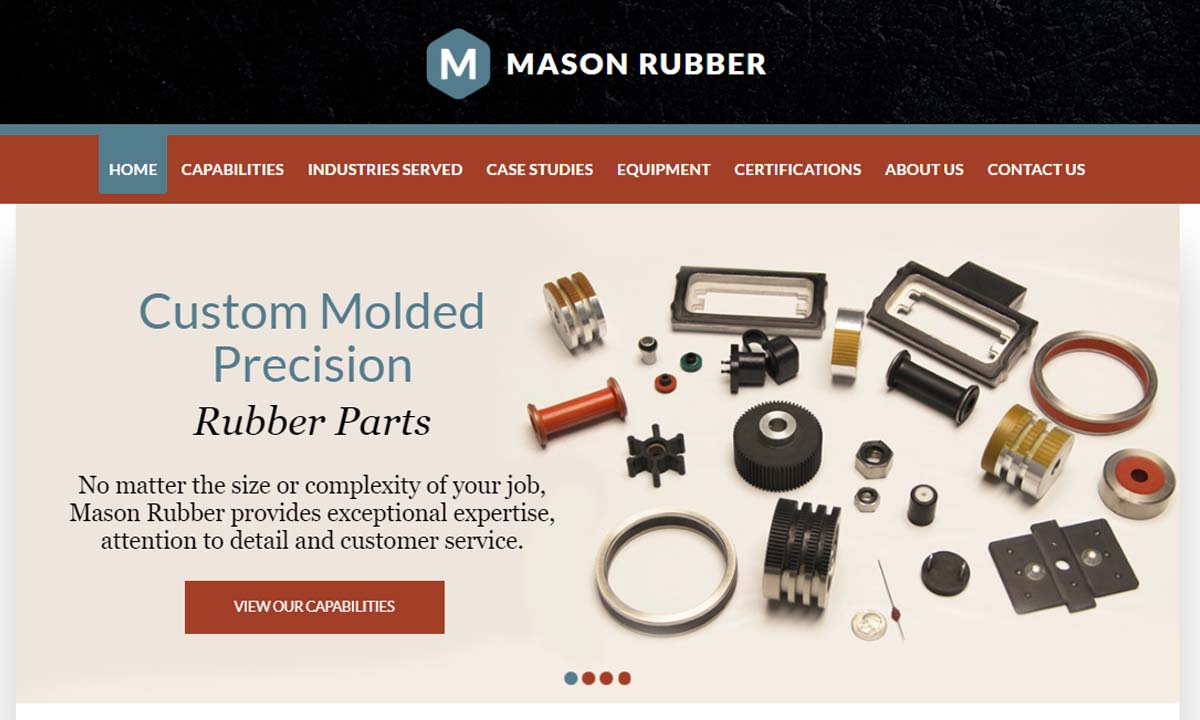

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

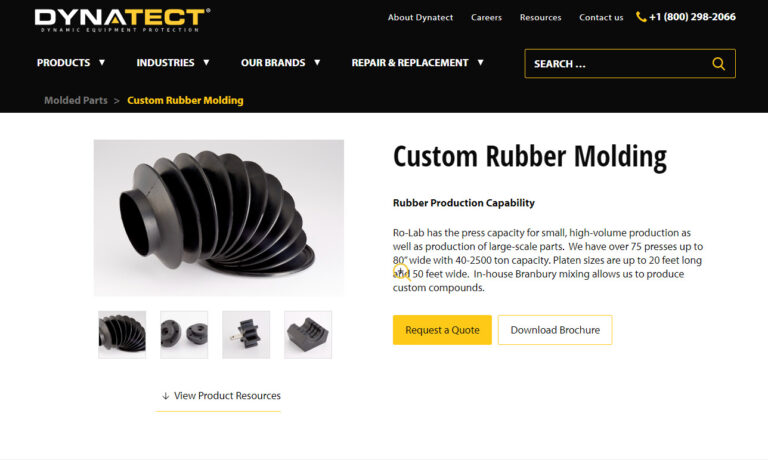

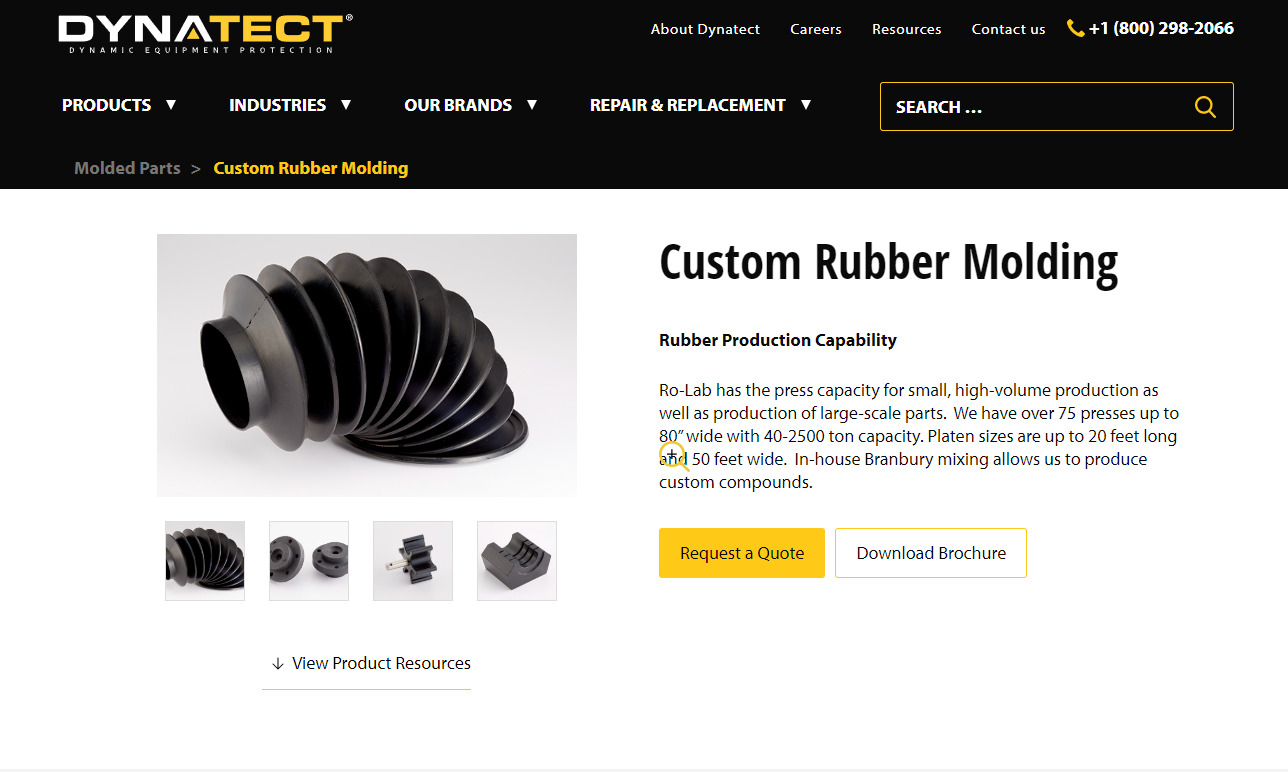

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Washer Companies

A screw or bolt can go through the middle of a rubber washer thanks to the hole in the material. It is possible to pass a larger object through the middle in some circumstances, such as a threaded pipe or conduit. The hole in the center of the washer should be smaller than any nut or other fastener used to secure it, and its overall diameter should be greater than the head of the screw or other hardware component that is inserted through it. The washer will be held in place thanks to this.

How Rubber Washers are Made

Depending on the desired use, compression or injection molding can be used to create rubber washers. The process of injecting molten plastic into a mold chamber that has been properly formed is known as injection molding. A quantity of uncooked rubber material is heated to a liquid state to start the process. When the rubber is molten, it is poured into a hollow that, in the fabrication of rubber washers, has the form of a washer. In the cavity, the rubber fills and shapes itself. The finished rubber washer is then created by allowing it to cool and harden.

The washer can then be made ready for delivery to consumers or, if more processing is required, delivered there. Similar to injection molding, compression molding involves applying pressure to the plastic while it is inside the mold cavity to ensure that it makes contact with all of the mold's curves. Both compression and injection molding are commonly employed, but generally speaking, injection molding is seen to generate more uniform results.

Types of Rubber Washers

The types of rubber washers include:

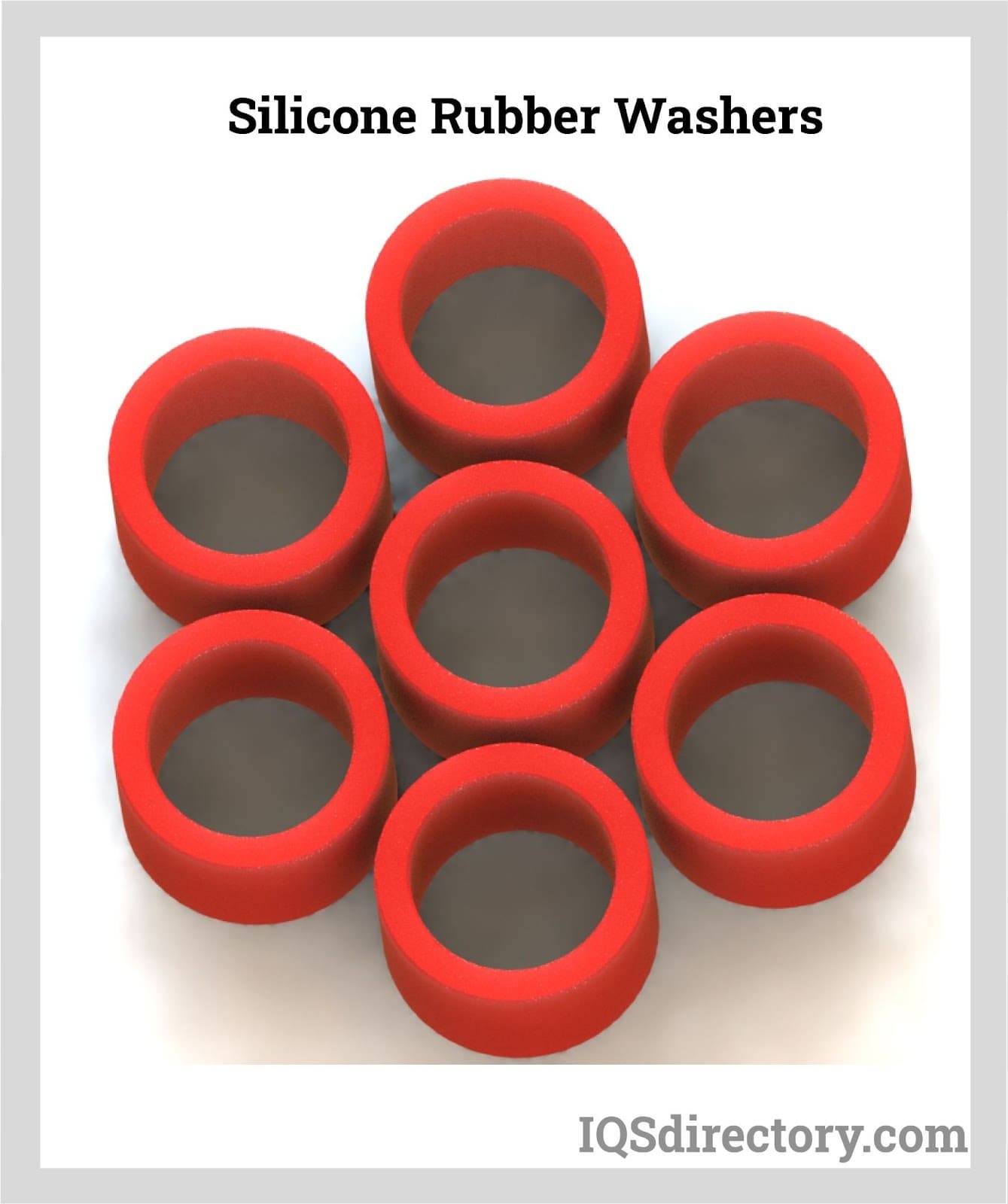

Silicone Rubber Washers

Silicone washers provide the widest temperature range currently available, withstanding high temperatures (about 150° to 500°F) in dry or humid environments. Additionally, they work with low compression sets and are fungal, UV, and ozone-resistant. Although petroleum oils and ketones don't function well with silicone, braking fluids and high-aniline point oils do.

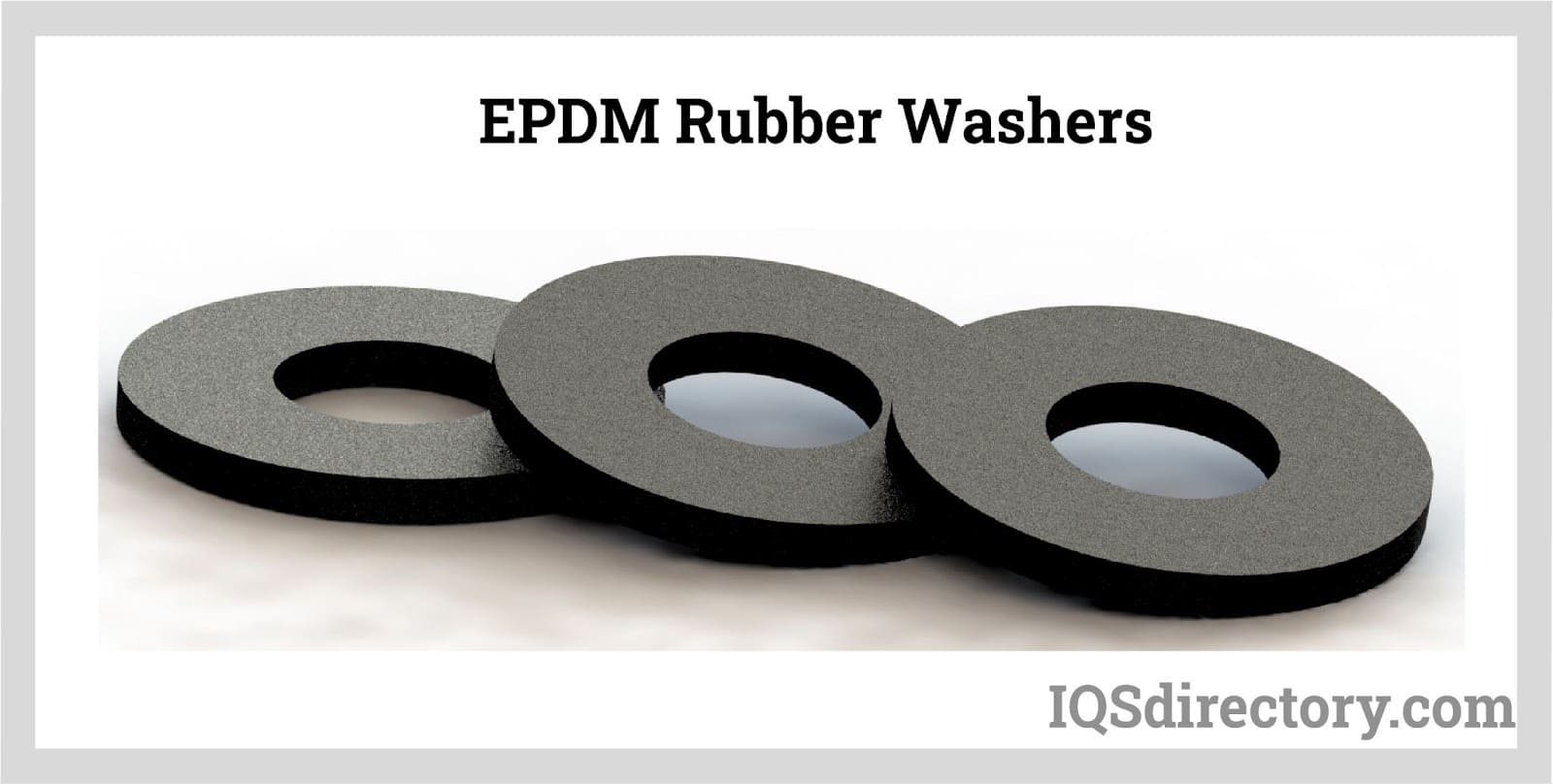

EPDM Rubber Washers

Rubber washers made of ethylene propylene diene monomer (EPDM) are resistant to weather extremes and temperatures between 60 and 280 degrees Fahrenheit. They are also resistant to ozone, steam, water, alcohols, and braking fluids and have minimal gas permeability. Dielectric properties of EPDM rubber washers offer good protection against electrical currents, ozone, and sunshine. It has great color stability and is heat resistant.

Neoprene Rubber Washers

These washers are highly ozone-resistant, have good oil, petroleum, and solvent resistance, and they weather the elements effectively. They work at a temperature range of 65 to 260 degrees Fahrenheit. They also withstand moderate acids, high-aniline point oils, and Freons. Neoprene rubber performs admirably in all elastomer applications.

Advantages of Using Rubber Washers

- Their water resistance makes them useful and more durable in a variety of applications. Due to this water resistance, they are better than metal washers in many situations because they are not susceptible to condensation's effects.

- Rubber washers provide more flexibility. Rubber washers make it easier to attach fasteners, effectively preventing leakage.

- They are excellent insulators; non-conductive grades are offered for applications requiring electricity. As a result, using them is risk-free and one won't get shocked by electricity.

- They are fluid-resistant and never rust because of this. Users don't need to be concerned about infection or harm.

Choosing the Correct Rubber Washer Manufacturer

To make sure you have the most productive outcome when purchasing rubber washers from a rubber washer manufacturer, it is important to compare at least 4 companies using our list of rubber washer manufacturers. Each rubber washer manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber washer company website using our patented website previewer to get an idea of what each manufacturer specializes in, and then use our simple RFQ form to contact multiple rubber washer companies with the same quote.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services