Ethylene, propylene, and diene monomers are the components of EPDM (ethylene propylene diene monomer), a synthetic rubber. Its single bond, chemically-saturated molecular structure gives it a very strong resistance to the elements. This is due to the fact that, unlike double-bonded rubbers, its molecular structure cannot be disrupted by ozone or UV rays. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

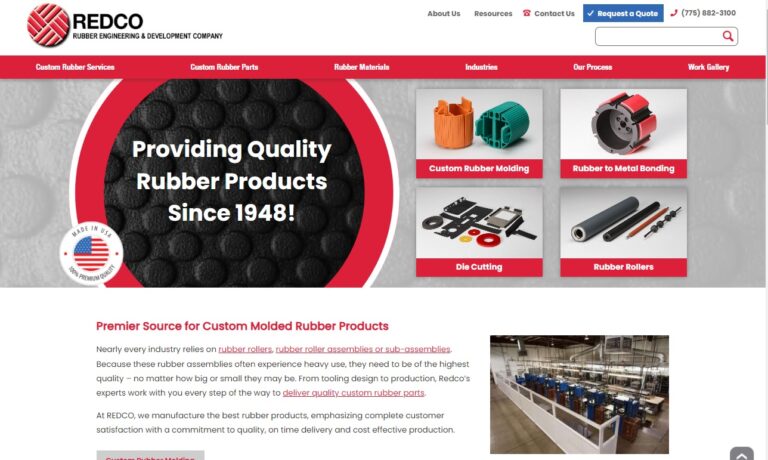

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

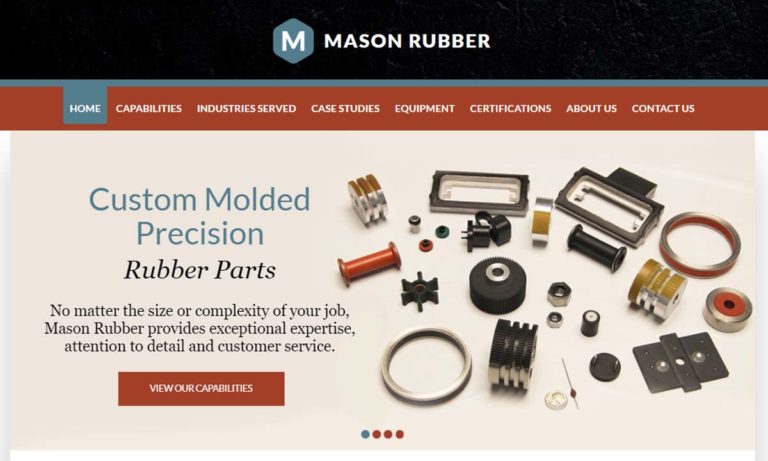

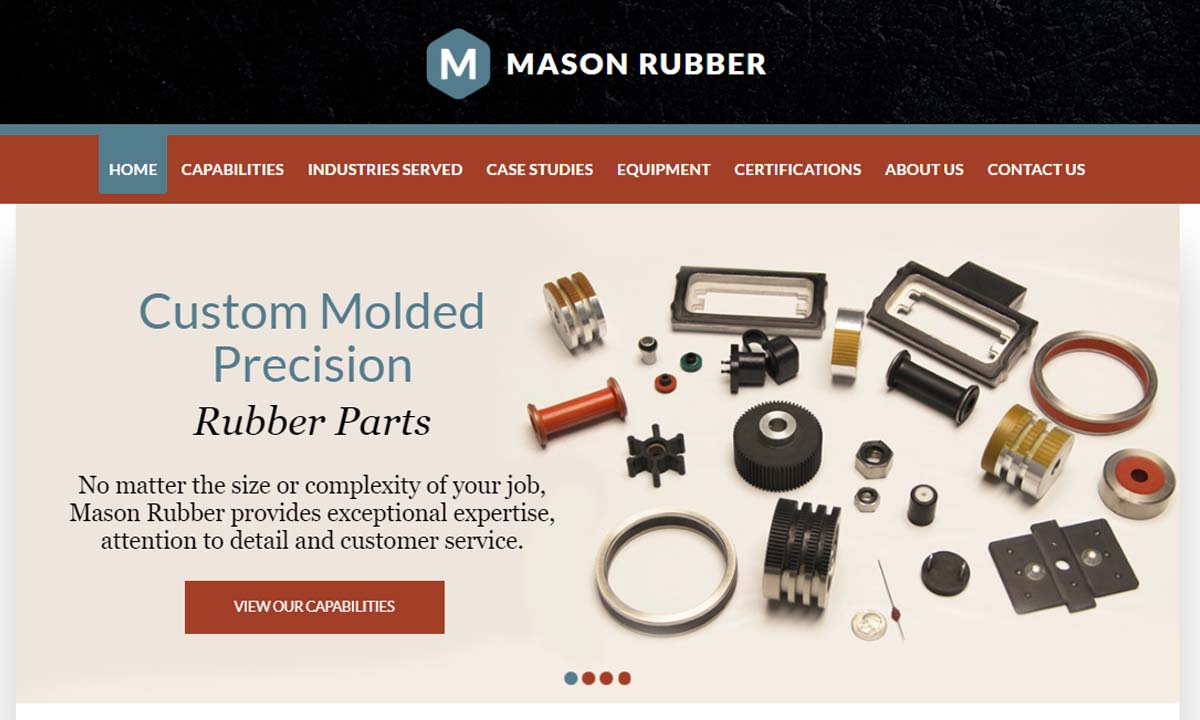

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

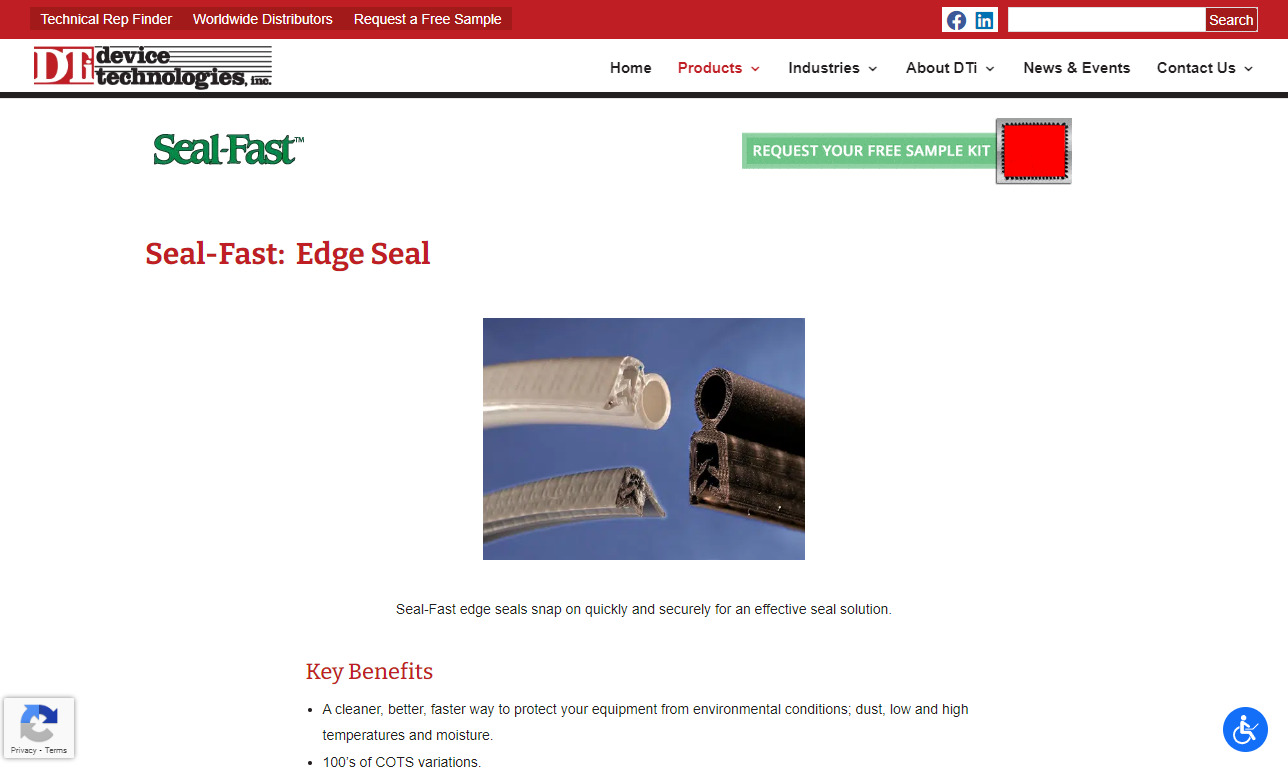

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

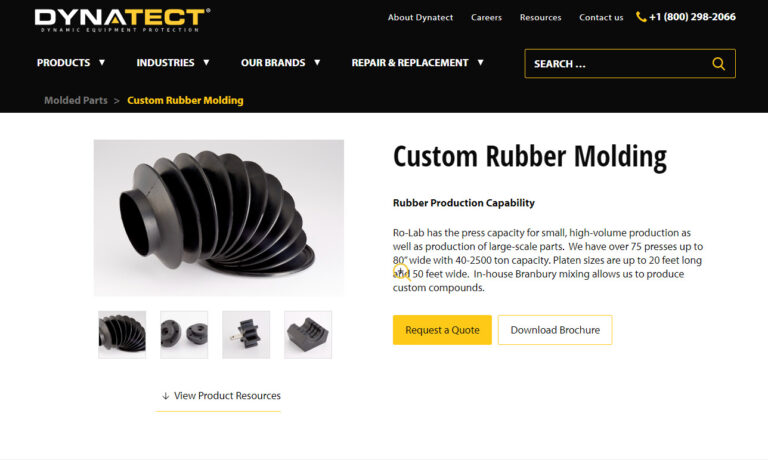

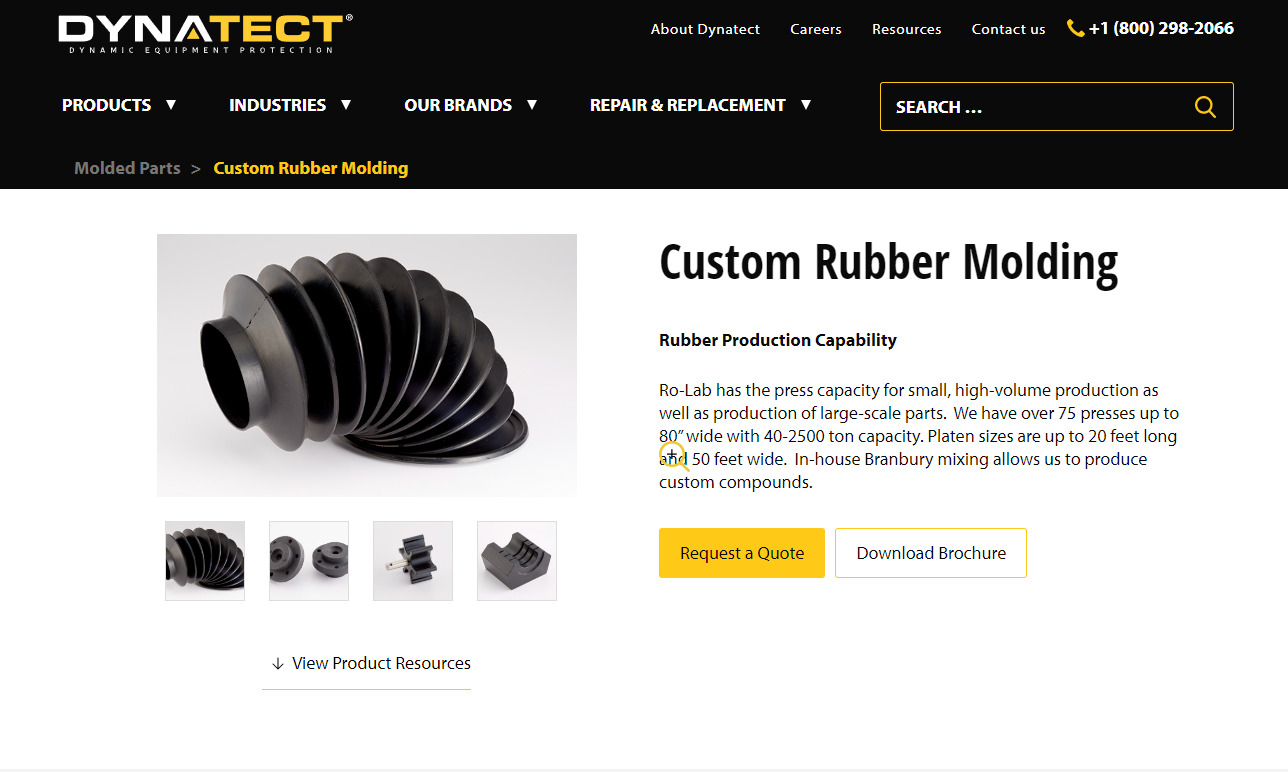

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More EPDM Rubber Molding Companies

Synthetic rubber includes EPDM rubber. It has a wide range of uses because of its extraordinary durability and flexibility, including in cars (where it is used for cooling system hoses, window and door seals, and more), cold rooms, non-slip deck and playground coatings, and many other places.

Simply said, while synthetic rubber (EPDM) maintains flexibility and can endure temperature changes for decades, pure rubber becomes brittle with temperature changes.

EPDM Molding Process

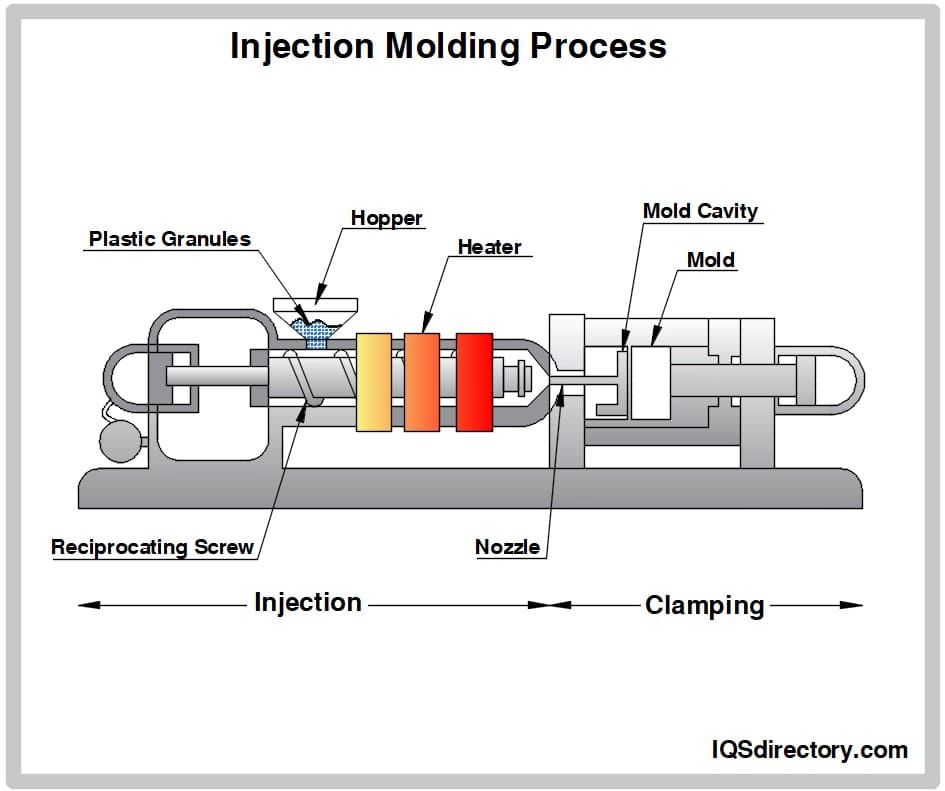

Closing the mold and pouring heated EPDM into the exposed mold cavity are the first steps in the procedure. For injection, a preset amount of EPDM is divided into smaller strips and put through a screw.

Vents allow displaced air to escape when the mold fills in order to avoid air bubbles and other flaws. Rubber compounds like EPDM are heated and subjected to much more pressure per square inch of cavity surface than plastics, which is one of the main differences between injection molding rubber and plastic.

High pressure and high temperature help plasticize the parts to cure the compound and plasticize the individual pieces, whereas plastic is cooled under less pressure. The length of time required for each cycle of parts to fully cure varies depending on the particular design. Once complete, the mold opens and the parts are manually removed or ejected so that the process can start over.

Advantages of EPDM Molding

- It provides exceptional resistance to UV, ozone, weathering, aging, and different chemicals.

- It is excellent for outdoor use.

- EPDM offers stability in temperatures that are extremely hot and low.

- It withstands steam and water.

- It provides low conductivity of electricity.

- EPDM has the ability to be used across a wide range of industries and applications.

- Its longevity and toughness are ideal for constant use.

- EPDM is cheaper than silicone.

- Eco-friendly: While white EPDM roofs are less common, they are still an option and can reflect UV rays and even help cut down on energy expenses. They work well with solar panel arrays and rooftop plants. Due to its lightweight nature, this material can adapt to any shape or style of roof while still offering the same benefits. Additionally, very little time or resources are needed to create this material, and it is completely recyclable.

Applications of EPDM Rubber

- Automotive: Thanks to its adaptability, toughness, and weatherability, EPDM is used in this application the most frequently. It can be found in wire and cable harnesses, brake systems, seals, weather stripping, and sealant for automobiles. Additionally, it is combined with other materials to create automotive bumpers, rub strips, and fender extensions.

- Industrial: EPDM is used in industrial applications because of its toughness, flexibility, waterproofing, and electrical-insulating qualities. Electrical insulators, connections for wire and cable, and parts like O-rings, hoses, and gaskets for water systems are all made of EPDM. Additionally, it may be found in belts, grommets, diaphragms, and accumulator bladders.

- Construction: EPDM is widely used in the roofing industry because of its qualities as an insulator, weatherproof material, and waterproof material. The sealant, expansion joints, garage door seals, pool and tank liners, and waterproof coating for bitumen roofs are additional uses for it. Even the roofs of RVs utilize it.

- HVAC: Due to its weatherability and temperature endurance, EPDM is used in this business as insulation, tubing, gaskets, seals, and grommets.

- Pond liners: Whether it's a pond, a water feature, or a stream, water is ideal for fostering a serene, natural atmosphere in outdoor settings. Doing so is really simple with EPDM pond liners! The pre-assembled pond liners are not only quick and simple to install, but they also have a 30-year lifespan. Additionally, EPDM is bleach resistant and toxic-free, making it ideal for fish, plants, birds, and other nearby species.

- Water tank liners: Because EPDM's molecules are so closely packed together, it is highly challenging for water and vapor to move through it. This makes it perfect for use in biogas and water storage tank linings. It also helps that it doesn't shrink or crack over time.

Choosing the Proper EPDM Manufacturer

To make sure you have the most positive outcome when purchasing EPDM from an EPDM manufacturer, it is important to compare at least 4 companies using our list of EPDM manufacturers. Each EPDM manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each EPDM company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple EPDM companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services