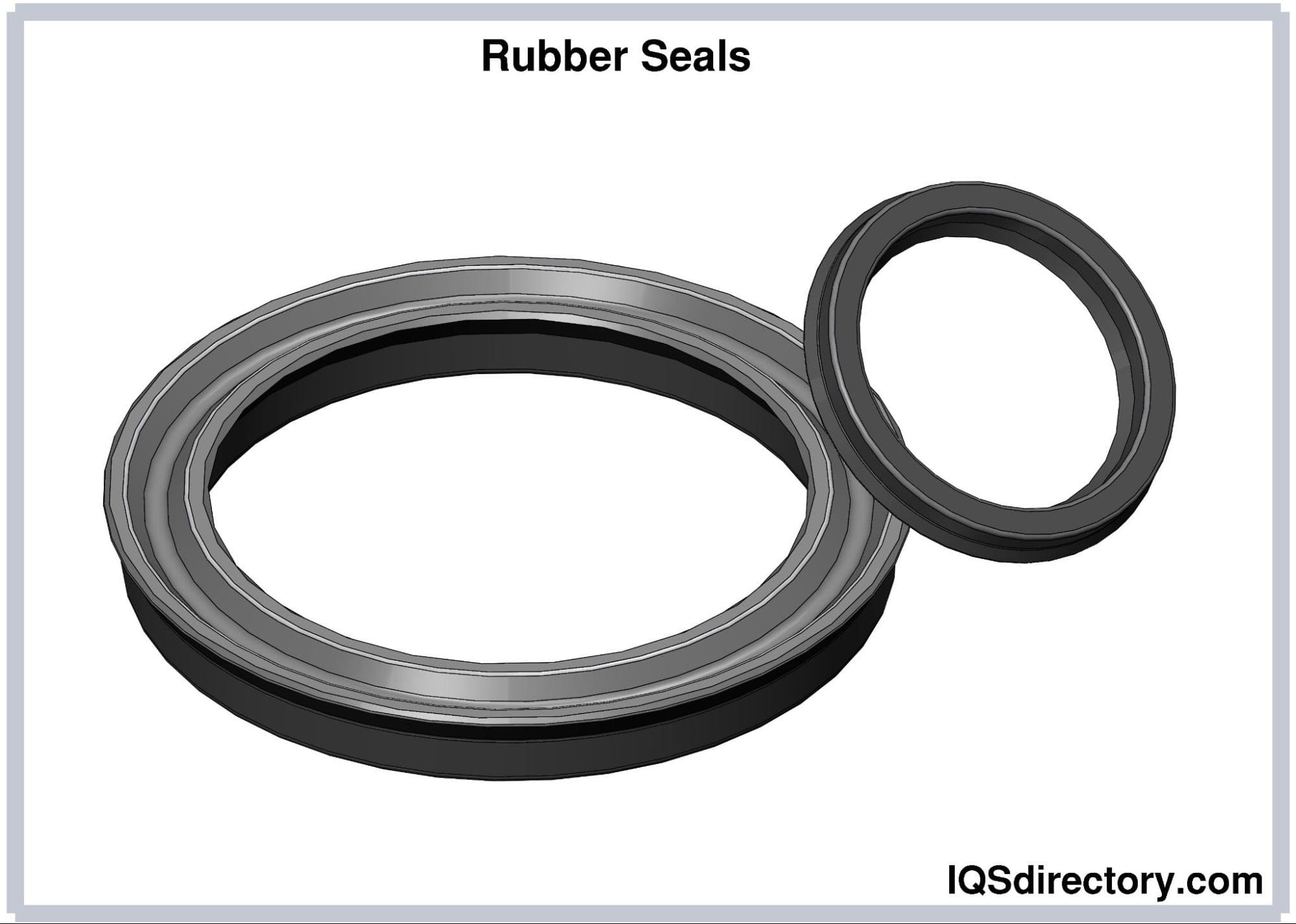

Rubber seals are made of natural or synthetic rubber and are used to close gaps, insulate areas from the elements or water, and prevent surface corrosion. Many commercial, industrial, and residential environments use rubber seals. Rubber seals are necessary for various manufacturing equipment types, particularly in operations involving pressured liquids or gasses. Some types of rubber sealant may also be used to protect machinery vulnerable to dust buildup or environmental factors. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

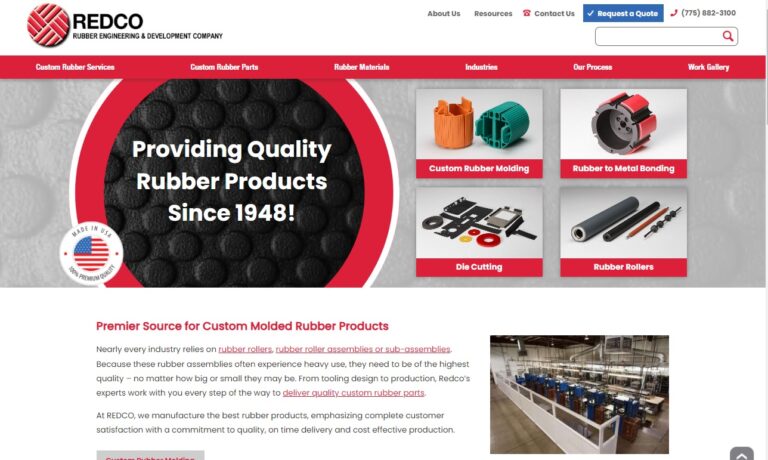

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

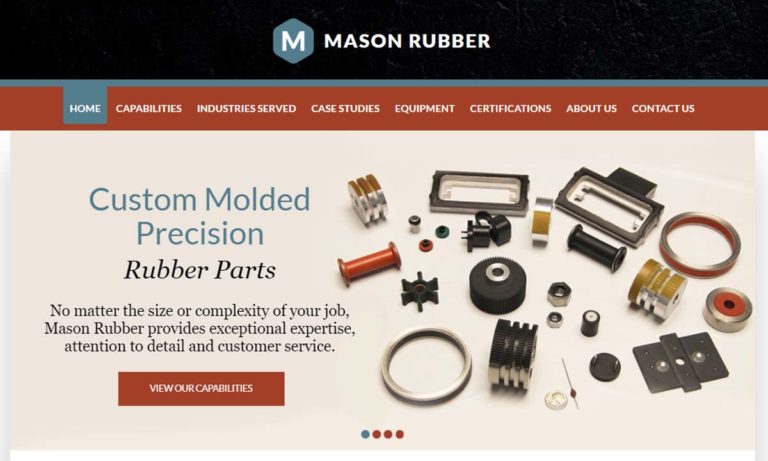

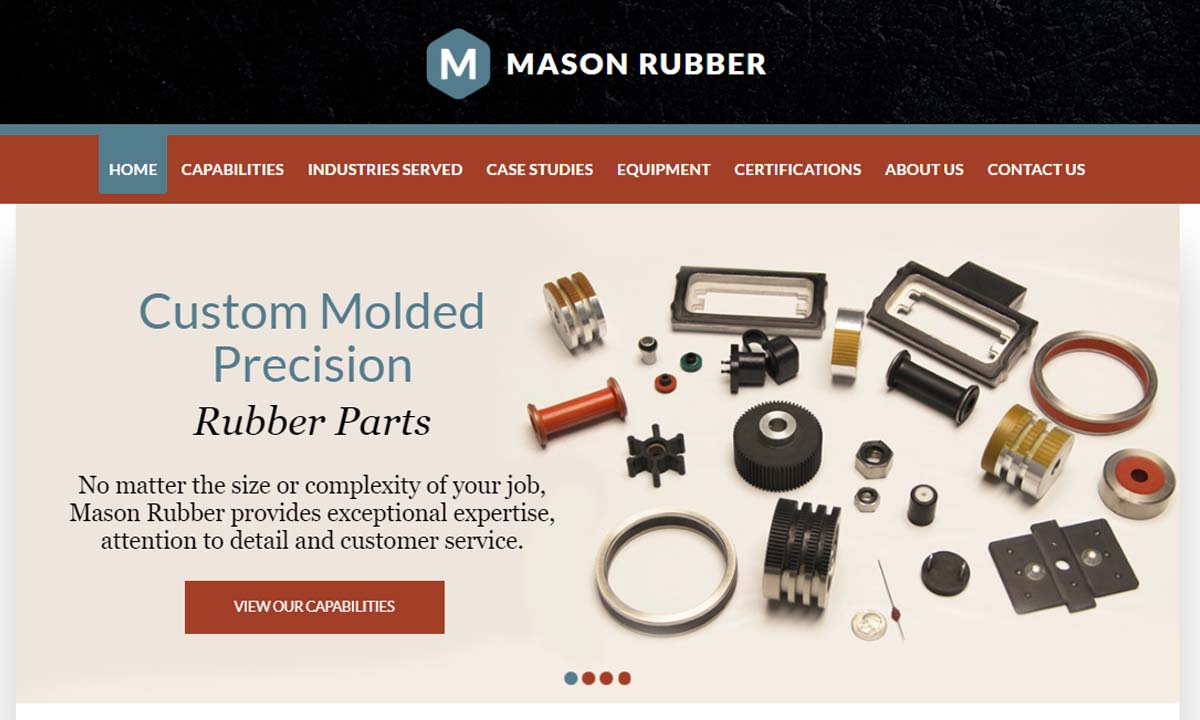

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

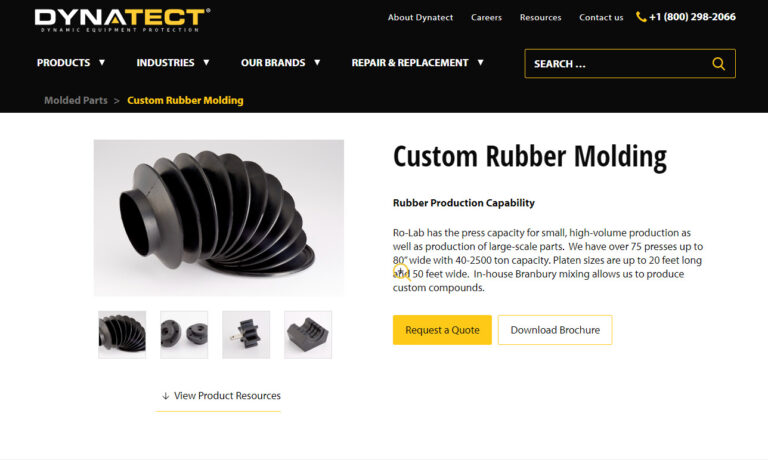

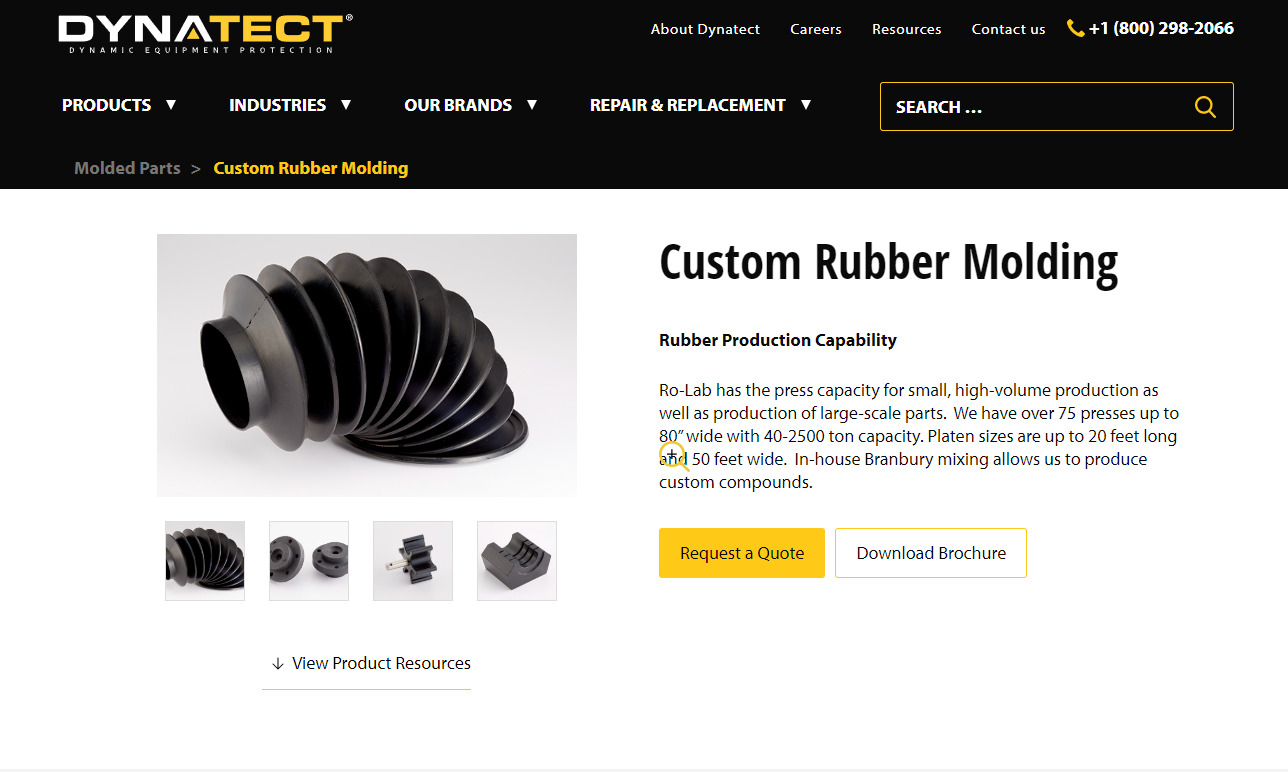

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Seal Companies

How Rubber Seals are Made

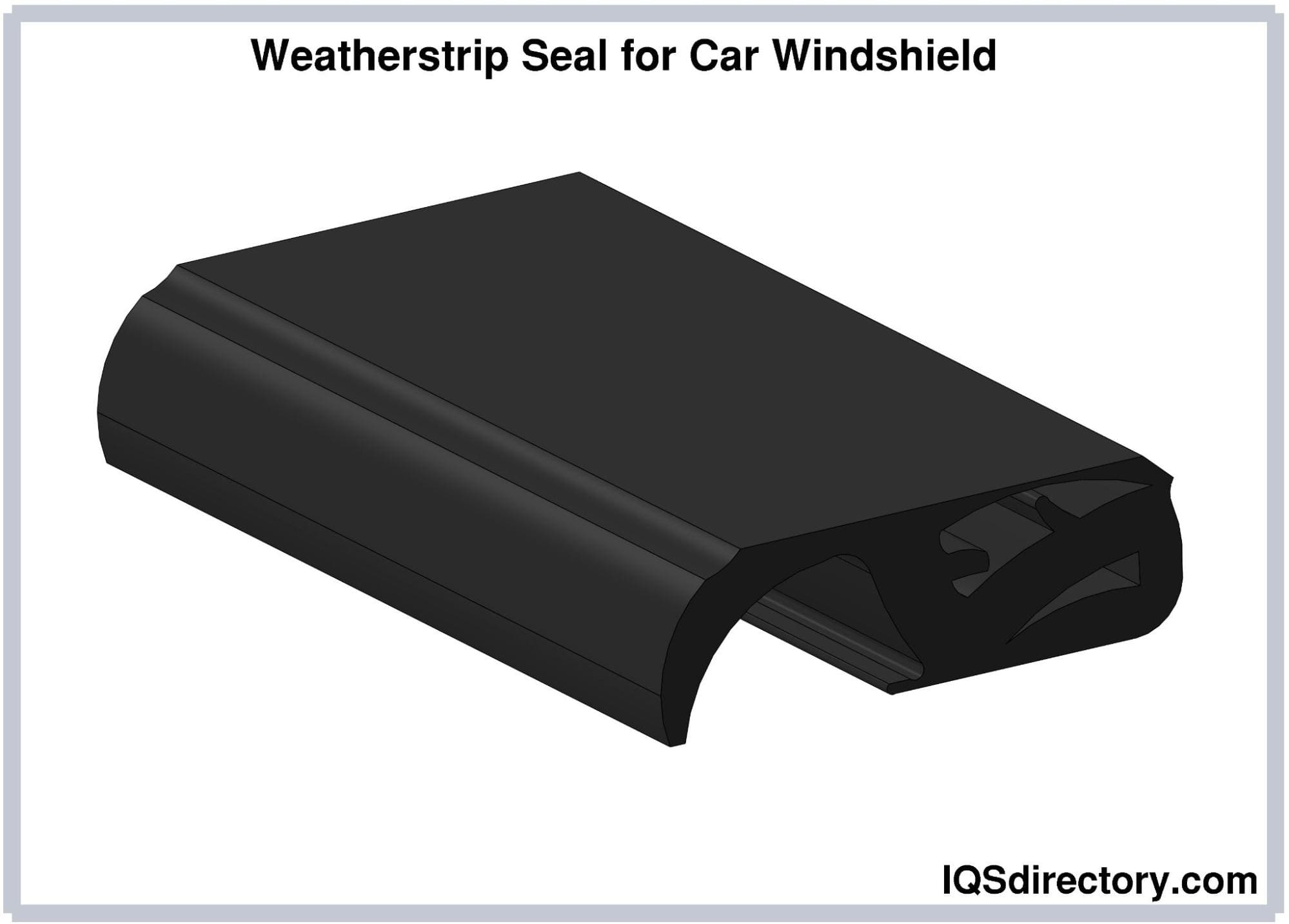

Rubber can be formed and reinforced using several techniques. Although extrusion and injection molding are the most popular thermoforming (heat forming) technologies, rubber seals can also be produced in other ways. Extrusion is the process of forcing molten rubber through a die, which is a hole in a metal plate that has been precisely formed.

By forcing molten rubber through a die, which takes the shape of the die, long profiles, strips, and channels can be made. Extrusion is generally utilized in rubber seals to produce long, thin seals for moisture management. Weatherstripping and rubber trim are two examples of extruded rubber seals.

Using injection molding, more advanced and specific rubber seals may be created. During injection molding, molten rubber is pressed into a mold cavity with the required seal shape. When the rubber is released from the mold, it cools, hardens, and transforms into a finished rubber seal. When a seal must fit into, around, or between surfaces, non-extruded rubber sealants are utilized. These sealants are frequently designed to be applied by end users as liquids or gels that quickly harden. Caulking and waterproofing materials are examples of applications for these different types of sealants.

Materials Used for Making Rubber Seals

EPDM

The synthetic rubber known as EPDM, referred to as ethylene propylene diene monomer, is incredibly adaptable. Because the material is designed to withstand wear and aging from ozone, sunshine, water, and other naturally-occurring elements, EPDM is frequently utilized for seals found in outdoor situations. In addition, with its lightweight, compressibility, and ease of die-cutting, EPDM is an affordable rubber material for door seals and other exterior applications.

Silicone

Silicone, with a working temperature range of -150 to 480° Fahrenheit, easily manages hot and cold situations. In addition, silicone is a desirable material option for die-cut, extruded, or molded seals because it has a high compression set and rebounding qualities.

Nitrile and Neoprene

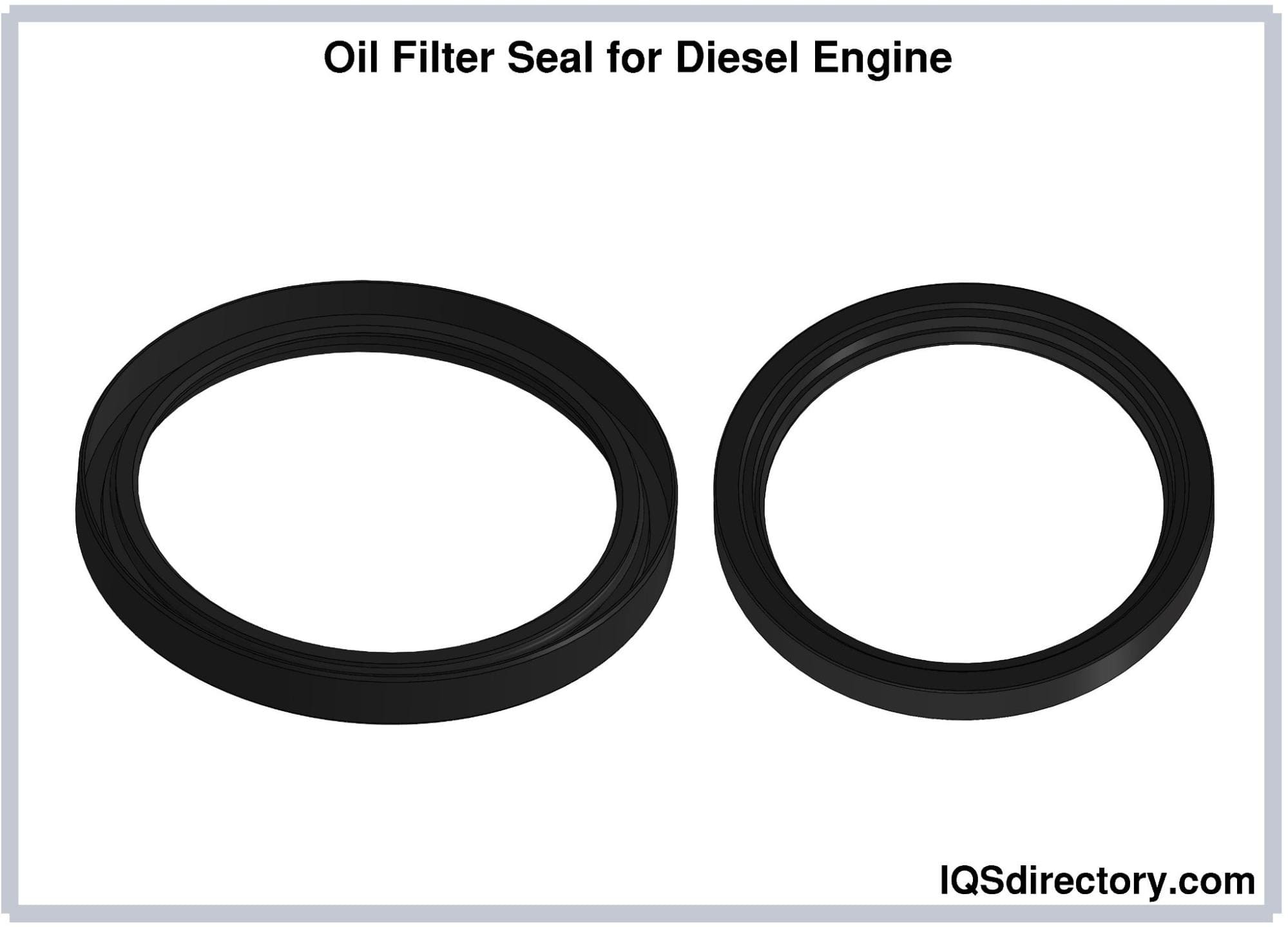

Both Nitrile and Neoprene are incredibly valuable materials for applications involving oil. Each material is designed to handle challenging contaminants, including acid, ozone, and oil. The predicted exposure to oils is different between Neoprene and Nitrile, though. While Nitrile works best for seals constantly exposed to oil or in locations where the oil is highly concentrated, Neoprene is designed to endure occasional exposure to oil and fuel.

Viton®

This substance has a high tensile strength, a low compression set, and great chemical resistance. This combination makes it a strong sealing option for temperatures up to 400° Fahrenheit or for intermittent usage at temperatures up to 600° Fahrenheit.

PVC

PVC is resilient to weather, oils, greases, and chemicals while being robust, light, and durable. PVC also has the benefit of being co-extruded into dual durometer parts, which makes it an ideal material for sliding parts like car door seals.

FiberFrax® and ManniGlas®

ManniGlas® and FiberFrax® are specialized seal solutions for high-temperature applications when silicone and other materials are insufficient. Both products, ManniGlas® and FiberFrax®, are built from compressed fiber materials and can endure temperatures of more than 1,000°F and 2,450°F, respectively.

Rubber Seal Applications

Rubber seals are crucial in marine and aeronautical applications where atmospheric stabilization is required. In addition, rubber seals are used in various consumer products, including garden hoses, pool pump systems, rubber gaskets for oil filters, kitchen appliances, bathroom fixtures, insulation, weatherstripping, and many more places. A rubber seal can be a gel, film, putty, or strip and stick to porous surfaces like glass, ceramics, concrete, paper, bricks, other rubber materials, textiles, leather, metal, and wood.

Advantages of Rubber Seals

Temperature Resistance

Rubber seals can tolerate extreme temperature variations and ranges. For example, silicone rubber seals can withstand temperatures up to 310° Celsius and as low as -100° Celsius. Due to this wide range, rubber seals are ideal for applications with extreme temperature variations.

Resilience

Rubber is more resilient than other materials and creates an impregnable airtight, waterproof seal. The fact that rubber is elastic and provides resistance directly proportional to pressure is even more significant. Rubber seals also keep their integrity for a long period.

Exceptional Flexibility

Rubber is used in various applications and can easily be shaped into different sizes and shapes. Common rubber seals are used on the three rings in the O, U, and V designs. Other types include bearing isolators, rotating oil seals, clearing seals, seals linked by a spring, and other seals.

Less Damaging

The majority of rubber seal types are non-toxic where they are utilized. Rubber won't damage the grooves or other elements with which it comes into contact. It also resists deterioration brought on by heat, ethylene oxide, electron beams, steam autoclaving, or gamma radiation sterilization.

Easily Sterilized

Rubber seals are ideal for the food, pharmaceutical, and medical sectors since they are non-toxic and compatible with various sterilization methods. Additionally, rubber has no impact on flavor or odor.

Choosing the Right Rubber Seals Supplier

To make sure you have the most positive outcome when purchasing rubber seals from a rubber seal supplier, it is important to compare at least 4 to 5 companies using our list of rubber seal suppliers. Each rubber seal supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each rubber seal business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rubber seal businesses with the same message.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services