The Plasticoid Company

The Plasticoid CompanyRequest A Quote

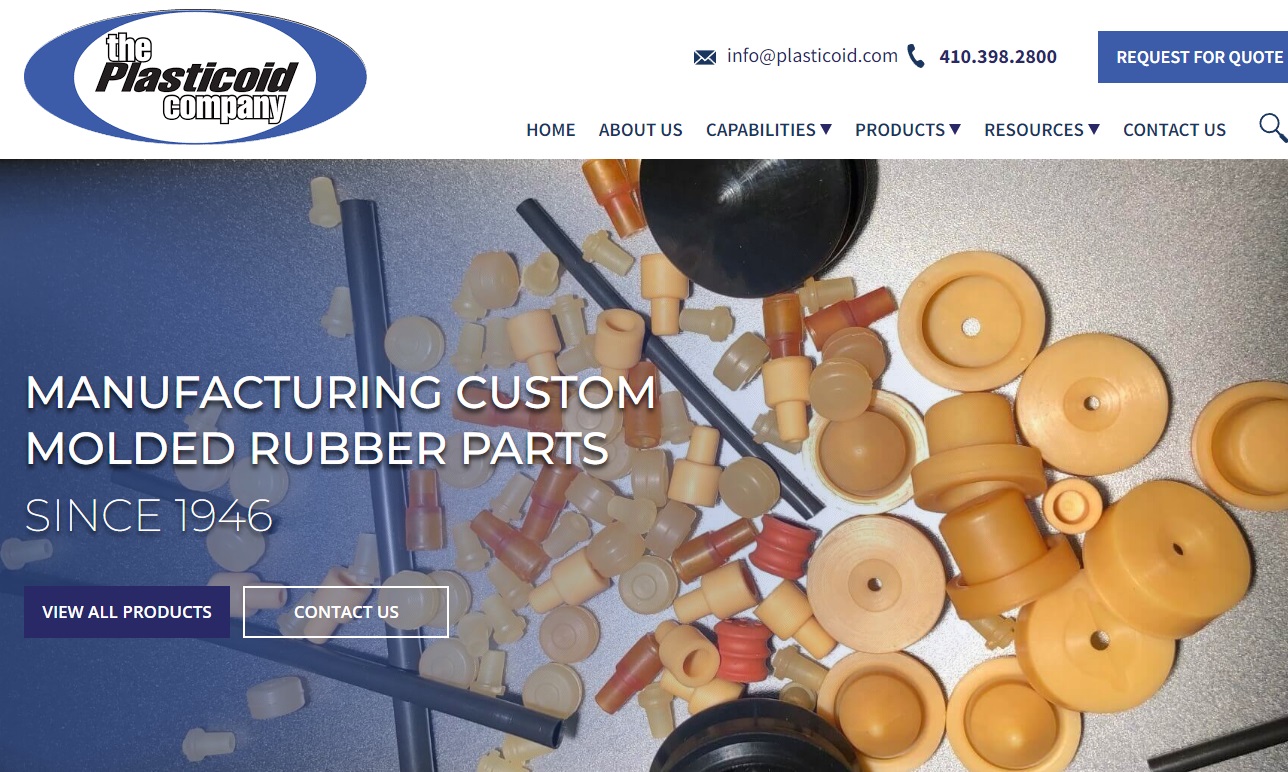

Elkton, MD | 410-398-2800The Plasticoid Company is a reputable and innovative provider of high-quality rubber molding products and services. With a rich history spanning several decades, we have established ourselves as a leading player in the rubber manufacturing industry, catering to diverse industries and clients worldwide. Our commitment to excellence is evident in every aspect of our operations. We specialize in the design, development, and production of precision rubber molded components, leveraging advanced manufacturing techniques and cutting-edge technology. Our extensive range of rubber molding products caters to a wide array of applications, including automotive, aerospace, electronics, medical, industrial, and consumer goods. At The Plasticoid Company, we take pride in our comprehensive service capabilities. Our highly skilled and experienced team of engineers, technicians, and manufacturing experts work closely with our clients to understand their unique requirements and provide tailored solutionsOur capabilities include compression rubber molding, precision die cutting, custom compound development, transfer rubber molding, and thermoplastic injection molding. Whether it's a custom rubber molding project or a high-volume production run, we possess the expertise and resources to deliver exceptional results. We Our state-of-the-art manufacturing facility is equipped with advanced machinery and equipment, enabling us to produce rubber molded parts of varying complexities, sizes, and specifications. We utilize a range of rubber materials, including natural rubber, synthetic rubber, synthetic polyisoprene, nitrile, SBR, silicone, EPDM, neoprene, and more, ensuring optimal performance and durability for our clients' applications. We understand the importance of responsiveness and timely delivery in today's fast-paced business environment. With our streamlined production processes and efficient supply chain management, we pride ourselves on meeting or exceeding our clients' project timelines without compromising on quality. The Plasticoid Company is a premier provider of rubber molding products and services, renowned for our technical expertise, advanced manufacturing capabilities, and unwavering commitment to quality. Whether you require precision rubber components for automotive applications, medical devices, or any other industry, we are your trusted partner in turning ideas into reality. Contact us today to explore how we can meet your rubber molding needs and help drive your success.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services