Mid-States Rubber Products, Inc.

Mid-States Rubber Products, Inc.Request A Quote

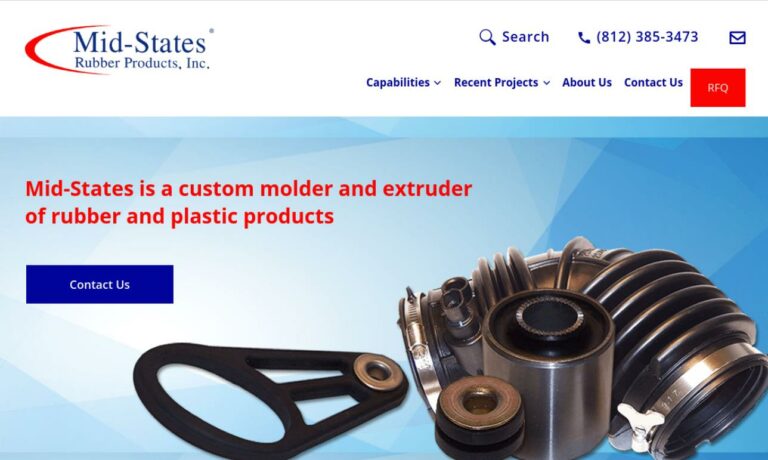

Princeton, IN | 812-385-3473Mid-States Rubber Products, Inc. is a leading rubber molding company based in Princeton, Indiana. The company has established itself as a trusted provider of high-quality rubber products and exceptional service to a wide range of industries. Their commitment to innovation, precision, and customer satisfaction has made them a preferred partner for clients worldwide. Mid-States Rubber Products specializes in the manufacturing of custom rubber molded products. They leverage their extensive expertise in rubber molding technology to produce a diverse range of products that meet the specific requirements and applications of their customers. Whether it's a simple rubber gasket or a complex molded component, Mid-States Rubber Products is dedicated to delivering superior quality and functionality. Mid-States Rubber Products produces precision-engineered rubber seals and gaskets for various industries. They also offer mounts, boots, diaphragms, bellows, and bushings. Mid-States Rubber Products goes beyond manufacturing quality rubber products. They offer comprehensive service capabilities that cater to the diverse needs of their clients. Their capabilities include mixing custom rubber compounds, thermal plastic injection molding, rubber extrusion, rubber finishing, deburing, compression molding, nad tansfer molding. Mid-States Rubber Products offers a wide selection of rubber compounds suitable for various applications. Their materials range from general-purpose elastomers to specialty compounds with enhanced properties such as high temperature resistance, chemical resistance, or electrical conductivity. With state-of-the-art facilities and advanced equipment, Mid-States Rubber Products possesses the capability to design and manufacture high-quality molds and tooling for rubber molding. Their skilled craftsmen ensure precise and efficient production processes, resulting in superior molded products. Mid-States Rubber Products, Inc. is dedicated to serving a diverse customer base, including automotive, aerospace, industrial, medical, and more. With their extensive experience, commitment to quality, and comprehensive service capabilities, they continue to be a trusted partner for clients seeking reliable rubber molding solutions.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services