Micro-Tronics

Micro-TronicsRequest A Quote

Tempe, AZ | 602-437-8995https://www.micro-tronics.com/

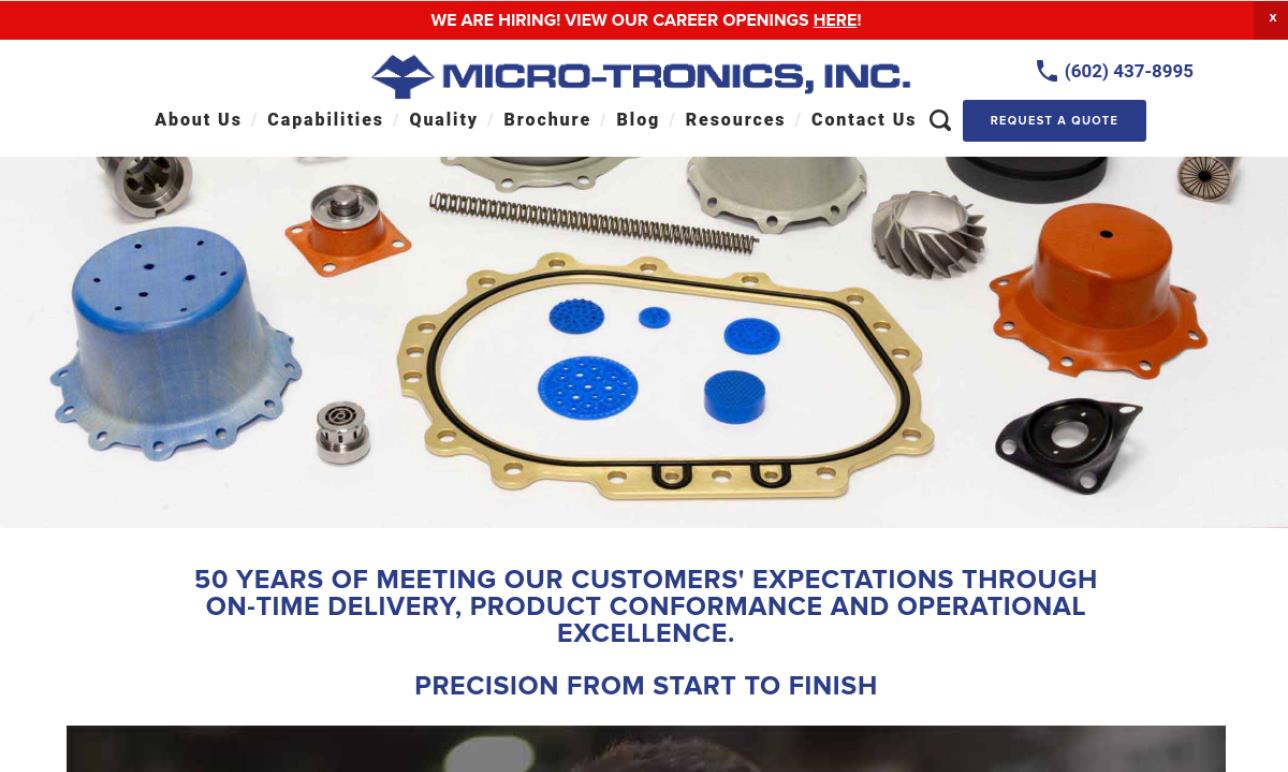

Micro-Tronics is a leading provider of rubber molding products and services, specializing in the manufacturing and customization of high-quality rubber components. Headquartered in Tempe, Arizona, our company has been at the forefront of the industry for over three decades, delivering innovative solutions to meet the diverse needs of our clients. At Micro-Tronics, we understand the importance of precision and reliability when it comes to rubber molding. Our state-of-the-art facilities and advanced technologies allow us to produce rubber parts with exceptional accuracy, durability, and consistency. Whether it's a small-scale project or a large-scale production run, we have the expertise and resources to deliver outstanding results. Our team of highly skilled engineers, technicians, and manufacturing professionals are dedicated to providing superior-quality products and services. We work closely with our clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From concept design and material selection to prototyping and final production, we offer comprehensive support throughout the entire rubber molding process. One of our core strengths is our extensive range of capabilities. We have the flexibility to work with various rubber materials, including silicone, EPDM, neoprene, natural rubber, and more. Our expertise extends across a wide range of industries, including automotive, aerospace, electronics, medical devices, consumer goods, and beyond. Our capabilities include custom rubber molding, multi-axis CNC milling, elastomer manufacturing, mechanical assemblies, and EDM capabilities. Whether it's gaskets, seals, O-rings, custom-molded parts, or any other rubber component, we have the knowledge and experience to deliver top-notch solutions. Quality is of utmost importance to us at Micro-Tronics. We adhere to stringent quality control measures to ensure that every product that leaves our facility meets the highest standards. Our commitment to excellence is further reinforced by our ISO 9001:2015 and AS9100 Rev D certified. Micro-Tronics is a trusted provider of rubber molding products and services. With our cutting-edge technology, extensive capabilities, and commitment to quality, we are well-positioned to meet the diverse rubber molding needs of clients across various industries. Partner with us for innovative solutions, superior quality, and exceptional service.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services