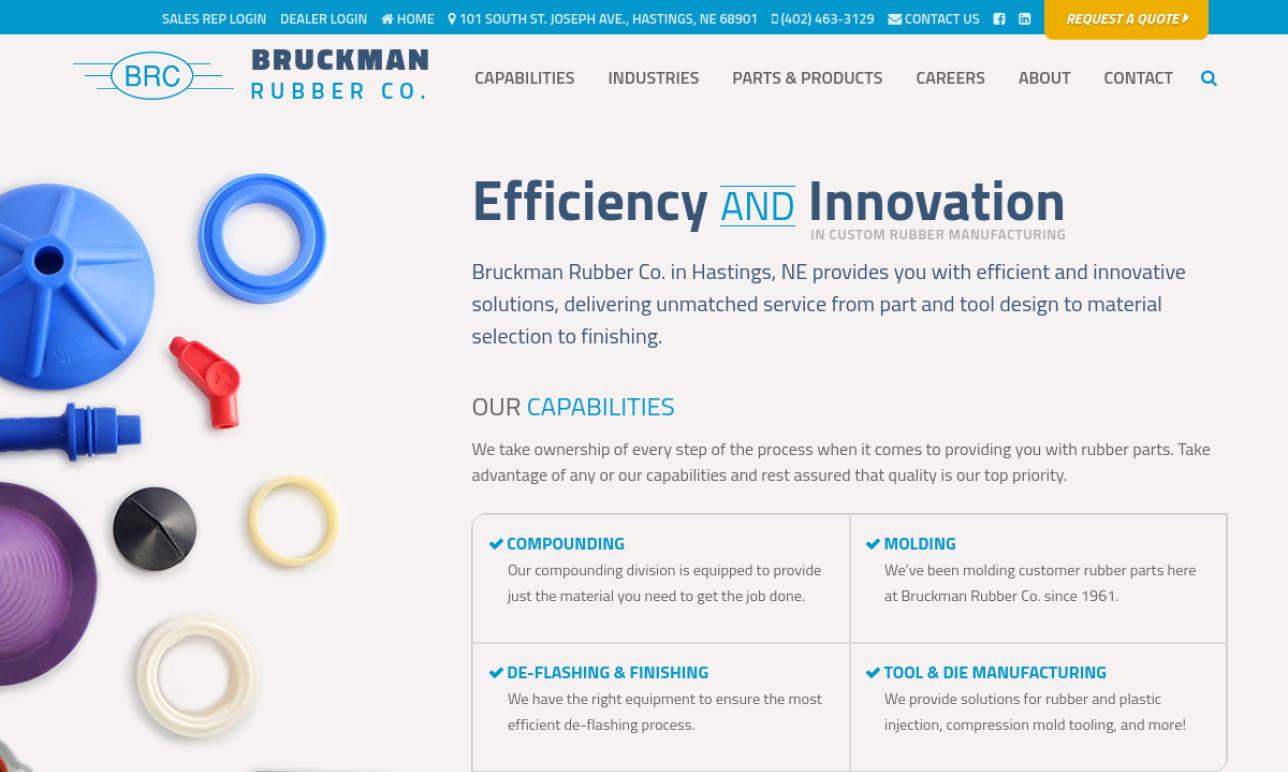

Bruckman Rubber Co.

Bruckman Rubber Co.Request A Quote

Hastings, NE | 402-463-3129https://www.bruckmanrubber.com/

Bruckman Rubber Co. is a leading provider of high-quality rubber molding products and services. With decades of experience in the industry, Bruckman Rubber has built a solid reputation for delivering exceptional solutions that meet the unique needs of its diverse customer base. Bruckman Rubber offers a wide range of products that are custom-designed and manufactured to precise specifications. Their extensive product portfolio includes rubber seals, gaskets, O-rings, custom rubber parts, and various other rubber components. These products are utilized across multiple industries, including automotive, aerospace, industrial manufacturing, oil and gas, and many others. One of Bruckman Rubber's key strengths lies in its advanced manufacturing capabilities, including compounding, molding, tool & die manufacturing, de-flashing, and finishng. This allows them to produce rubber products with exceptional precision, durability, and consistency. Bruckman Rubber's skilled team of engineers and technicians work closely with customers throughout the entire manufacturing process, from design and prototyping to production and quality control, ensuring that the final products meet or exceed expectations. At Bruckman Rubber, customer satisfaction is paramount. The company takes a customer-centric approach, striving to understand the specific requirements and challenges faced by each client. By leveraging their extensive technical expertise and industry knowledge, Bruckman Rubber delivers tailored solutions that address the unique demands of various applications. Whether it's a high-volume production run or a small batch order, the company is committed to providing exceptional products with quick turnaround times. Furthermore, Bruckman Rubber places a strong emphasis on quality assurance. Their manufacturing facilities adhere to stringent quality control measures to ensure that every product leaving their premises meets the highest standards. They have experience designing rubber-molded solutions for transportation, oil & gas, medical, agricultural, and recreational applications. Bruckman Rubber also offers a range of value-added services to enhance their customers' experience. These services include material selection guidance, design assistance, prototyping, tooling fabrication, and supply chain management. By providing comprehensive support throughout the product development lifecycle, Bruckman Rubber ensures that their customers' projects are executed efficiently and effectively. Whether you require custom rubber components for automotive applications, industrial equipment, or any other specialized use, Bruckman Rubber Co. stands ready to meet your needs with precision, efficiency, and unmatched customer service.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services