Rubber grommets are a type of wiring equipment accessory. They are used for cables passing through holes. The wires are protected from being severed by sharp plate slicing and are also dustproof and waterproof. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

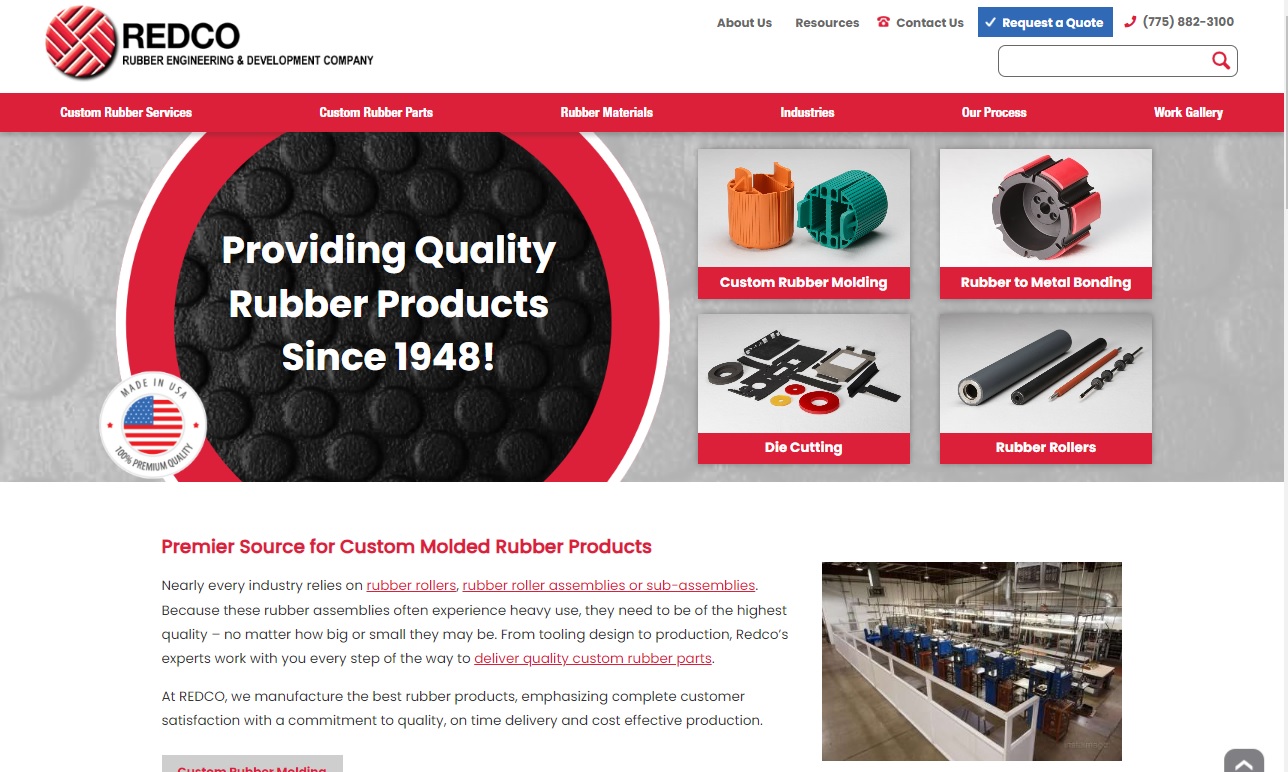

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

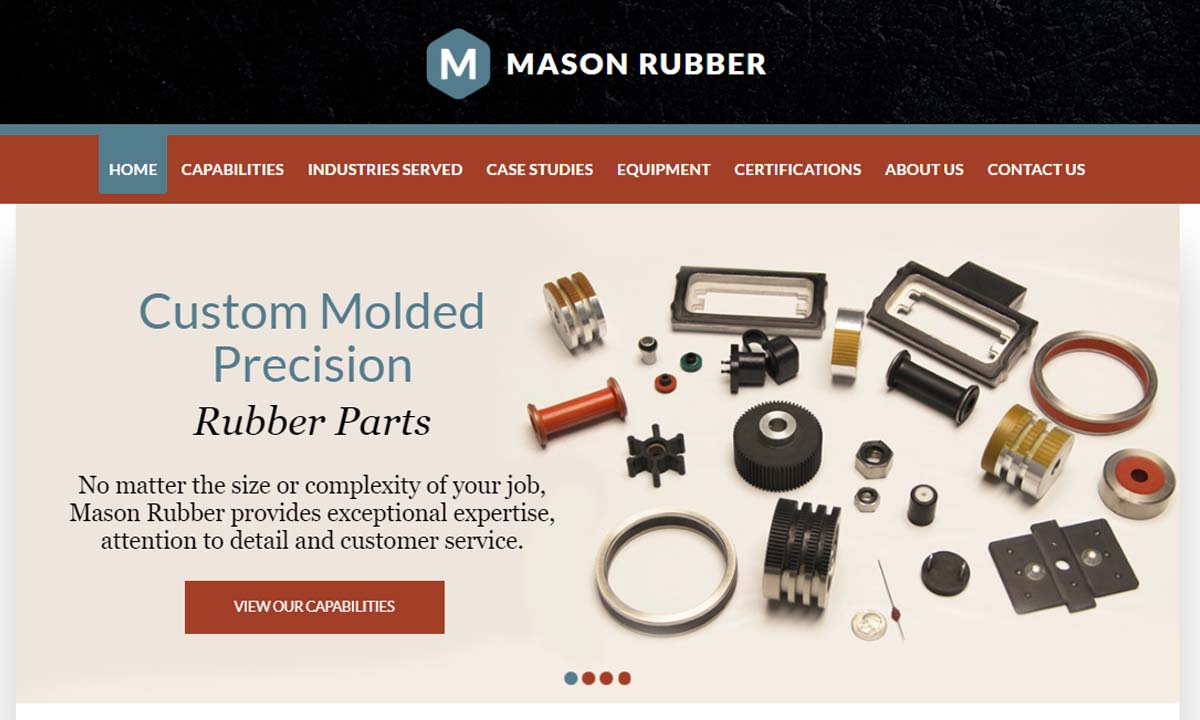

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Minnesota Rubber and Plastics (MRP) is a leader in material compound development and the manufacturing of custom elastomeric and thermoplastic components. With facilities across North America, Europe, and Asia, MRP collaborates with original equipment manufacturers to solve difficult sealing and component challenges across multiple markets. Capabilities include materials science and formulation,...

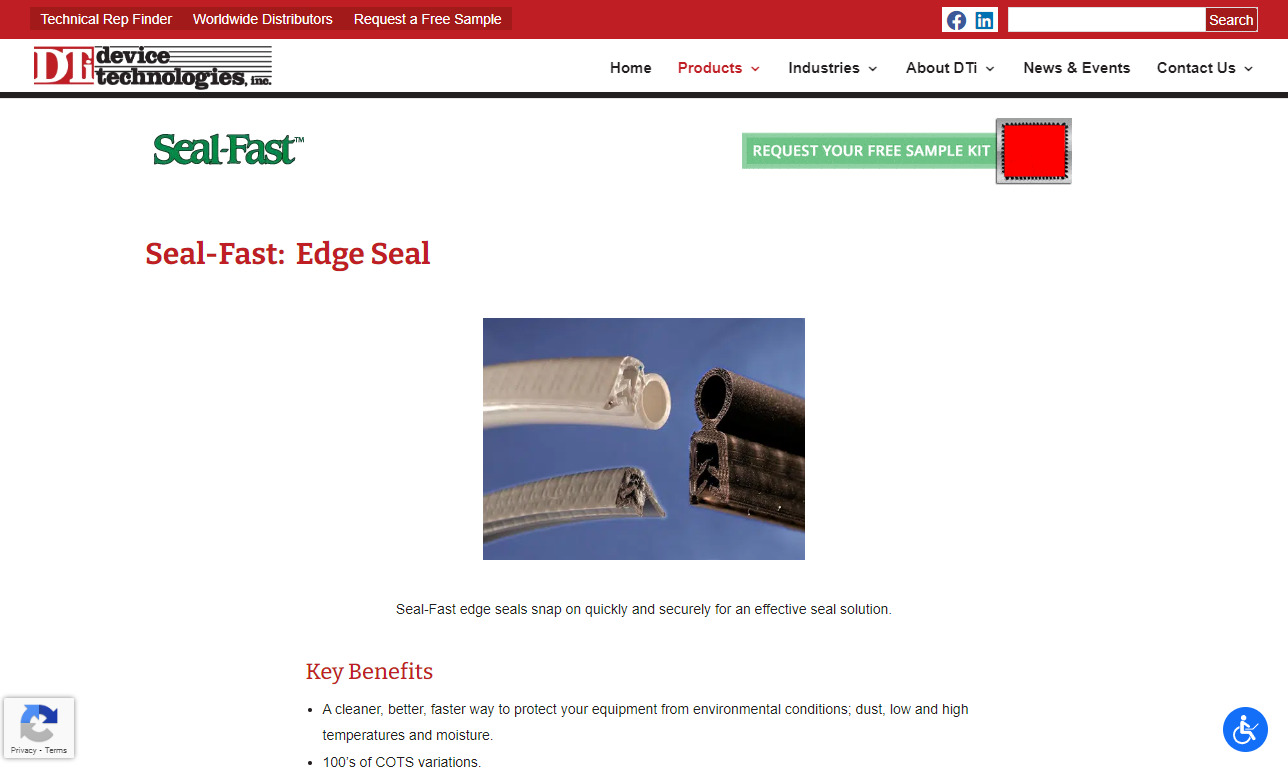

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

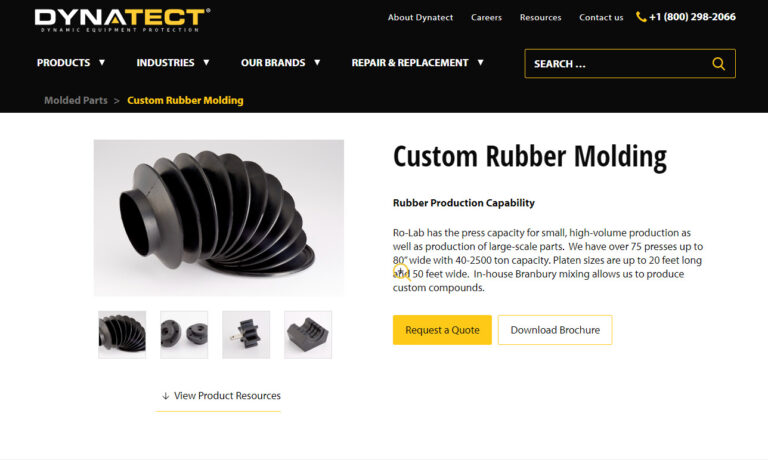

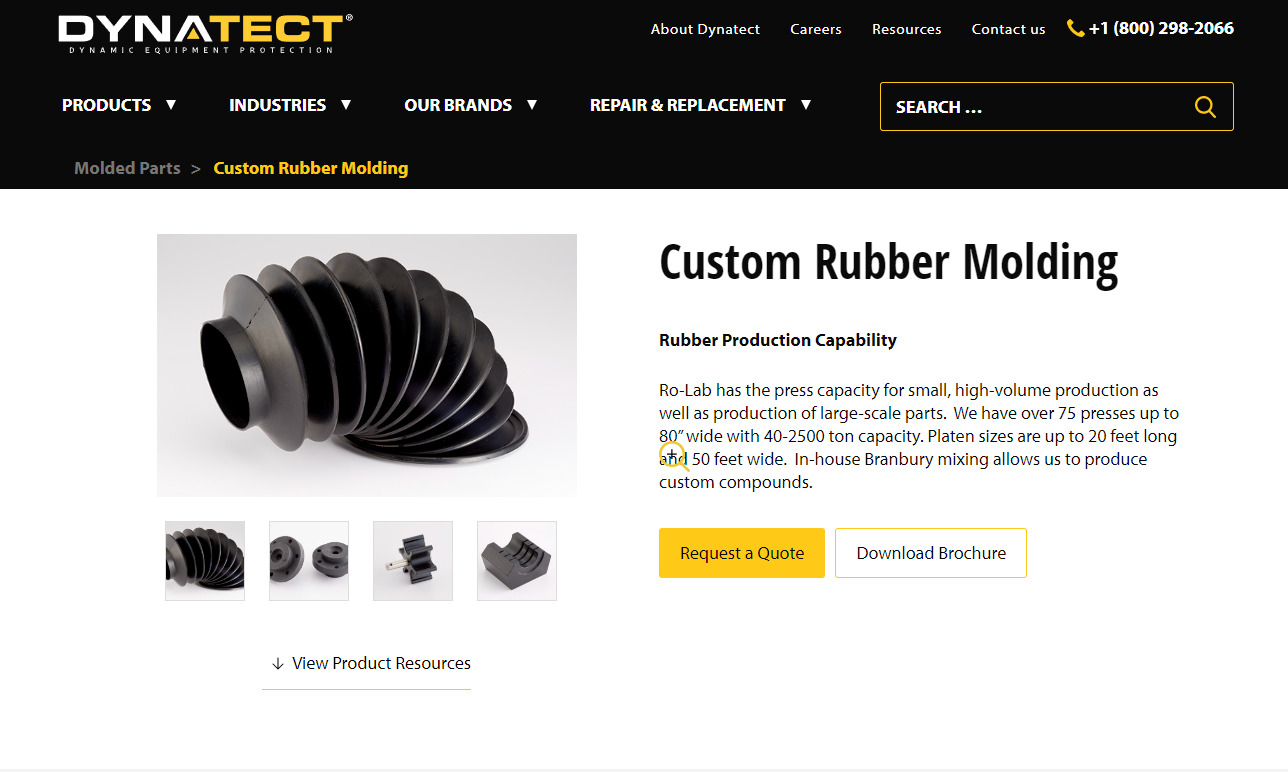

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Grommet Companies

There are several crucial applications for grommets, which fulfill a variety of significant functions. Grommets are typically employed in building, manufacturing, and other related industries to conceal the rough and jagged edges of a hole in metal. This is carried out to safeguard the substance being transported through the opening. A two-piece plastic grommet can pass a wire through a metal hole. If you must avoid tugging a power cord or wire at any cost, this grommet effectively and safely grips the wire and is a vital addition.

Additionally, rubber grommets are crucial components in automotive applications. They prevent chafing or grazing lines, wires, and cables on difficult terrain. They are used to seal a variety of significant under-the-hood and body applications and can also effectively reduce vibration.

How Rubber Grommets Are Produced

Although they can also be molded, rubber grommets are typically manufactured from extruded rubber. During the extrusion process, raw rubber is heated and pressurized as it is pressed through machinery. Once molten, the rubber is pressed through a die, a device used to mold raw materials into useful goods. The rubber is cut into a finished grommet once it has emerged out the other side of the die and has time to cool and solidify. However, extrusion is not necessarily a good grommet fabrication procedure because it can only create extremely simple shapes. More complex shapes can be created using injection and compression molding procedures. The rubber is heated at the beginning of both procedures, much like in extrusion.

Material Options for Rubber Grommets

- Natural Rubber Grommets: Natural rubber grommets have a high tensile strength and tear strength, making them sturdy and resistant to cracking. Additionally, they have exceptional insulating qualities.

- NBR Grommets: Compared to other rubber materials, this is the best material for oil resistance. NBR is the ideal material for rubber grommets that come into contact with oil. NBR is a semiconductor rubber material with low volume resistance and antistatic qualities.

- Neoprene Grommets: Excellent heat resistance, ozone aging resistance, and weather resistance are all characteristics of neoprene rubber grommets. They are appropriate for outdoor products and can function in direct sunlight. The neoprene material is also utilized for high flame resistance applications.

Types of Rubber Grommets

- Open rubber grommets: An open rubber grommet, the simplest type, has a singular central hole. When cables and pipes pass through holes in metal plating, these grommets are used to protect them.

- Closed rubber grommets: Closed grommets, often called blind rubber grommets, are an excellent option for sealing unused holes to prevent dust accumulation. They offer airtight seals when applied. Blind rubber grommets lack a central hole, unlike other grommets with a similar form. The semi-blind grommet is another variation. These have a membrane in the center with a narrow opening for cables or wires to pass through. This implies that semi-blind grommets can replace both open and closed grommets.

- Rubber grommet strips: Rubber grommet strips are different from other designs. They are strips that sit along a panel or plate's edge and smooth it down. They come in sticky varieties and can be trimmed to size.

- Stepped rubber grommets: The typical shape of stepped rubber grommets is a tapering cone with spaces in between. These lines indicate where the grommet can be trimmed to various sizes. They are perfect for sectors that use a variety of cable diameters because of their adaptable nature.

Advantages of Using Rubber Grommets

- Grommets made of rubber are more weatherproof.

- Additionally, they are less impacted by the harmful effects of ozone and UV rays.

- They are extremely heat resistant.

- This kind of grommet is stronger and less likely to tear.

- They do not easily dry out, crack, or come loose.

- Rubber grommets are more resistant to acids, including phosphoric, hydrochloric, sulfuric, and saltpeter.

- Compared to other grommets, they can also withstand wider temperature ranges.

- Rubber grommets can only be inserted on one side, making installation quicker and simpler. Attaching a lock nut is not needed to reach the opposite side of the installation.

- Given that it doesn't protrude or take up much room, rubber grommets are good for use in small spaces.

Choosing the Correct Rubber Grommet Manufacturer

To make sure you have the most beneficial outcome when purchasing rubber grommets from a rubber grommet manufacturer, it is important to compare at least 4 manufacturers using our rubber grommet directory. Each rubber grommet manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber grommet business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rubber grommet businesses with the same quote.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services