Rubber molding manufacturing involves shaping raw rubber materials into functional products. Rubber molding is an operation in which raw melted rubber takes form inside a mold.

While some products can be made by other rubber shaping processes such as cell casting and extrusion, the molding process has its own features that set it apart. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to...

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both...

Minnesota Rubber and Plastics (MRP) is a leader in material compound development and the manufacturing of custom elastomeric and thermoplastic components. With facilities across North America, Europe, and Asia, MRP collaborates with original equipment manufacturers to solve difficult sealing and component challenges across multiple markets. Capabilities include materials science and formulation,...

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO...

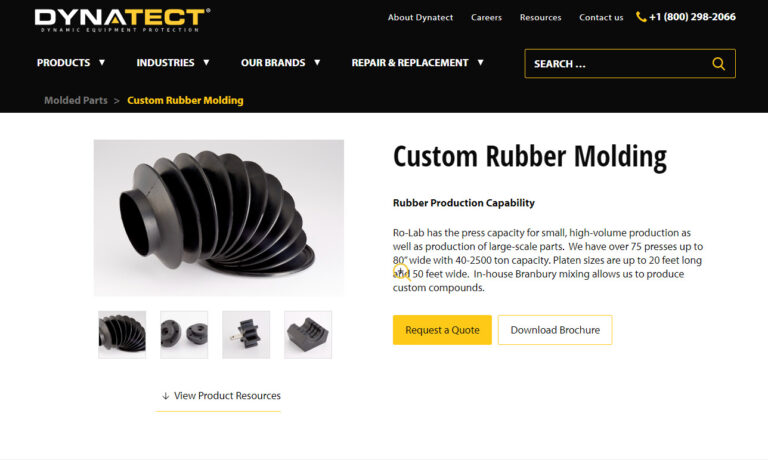

At Dynatect Ro-Lab, Inc., we pride ourselves on our expertise in rubber molding, offering a comprehensive range of solutions to meet diverse industrial needs. With a rich legacy in the field, we have honed our capabilities to excel in both large and small parts in either low- or high-volume.

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Molding Companies

Products that are made through rubber molding are enclosed in a mold cavity instead of a die, and can thus be made into complex and irregular shapes.

Rubber Molding Applications

To one extent or another, molded rubber products span across every industry. Examples of these industries include: medicine and healthcare, electronics, aerospace, automotive manufacturing, transportation, sports and recreation, EMI shielding and sound management.

Countless products are made using the rubber molding process, due to its precision results. Rubber molded parts can be designed to fit into any piece of equipment without any risk of leakage. In addition, because of the existence and capabilities of synthetic rubber, industries such as health care, can make use of numerous applications while reducing the health risk. For instance, alternative materials are available for people with latex allergies, and intravenous fluids can pass safely through silicone tubing without causing allergic reactions.

Products Produced from Rubber Molding

Many kinds of complex rubber products are made this way. Examples include: oil and gas components, fluid pumps, rubber diaphragms, customized buttons, vibration absorbers and isolators, rubber seals, rubber grommets, rubber washers, rubber bushings, cable boots, EMI shielding products, surgical instrument parts, blood analysis machines, keypads, electrical connector inserts and rubber sheet.

Rubber Grommets

Rubber grommets are a useful component that is used extensively for industrial, consumer, and commercial purposes. Rubber grommets are made to fit around a hole in a surface, protecting wires or other hardware that must pass through it. Grommets can also protect the hole itself from wear or damage. Rubber grommets can be found protecting wires from becoming disconnected, or aligning the holes in desks which allow safe passage for computer wires.

Rubber Washers and Rubber Bushings

Since many manufacturing machines contain moving parts that can vibrate excessively, rubber washers and rubber bushings are installed to secure these moving parts and absorb vibration in an effort to protect the people operating them.

Rubber Sheet

A rubber sheet is a large, thick sheet that reduces vibration and noise in a machine when placed underneath it. The reduction of vibration and noise can greatly improve overall safety and working conditions.

History of Rubber Molding

Natural rubber has likely been in use in some form or another for a very long time. Specifically, some South American tribes report that their people have been using rubber tree sap to make household items for thousands of years. In addition, we believe that rubber was used by the Mayans as far back as 1600 BC. Rubber molding, though, didn’t really start taking place until after the development of vulcanization. Once scientists learned how to do this, they could process rubber without degrading it.

Before vulcanization, people were using rubber, but with less success. It all began in 1823, when Scottish chemist Charles Macintosh discovered that by applying rubber mixed with a coal-tar byproduct to one cloth, he could glue it to another. The use of rubber products quickly spread across Europe and to the United States. Time and time again, rubber product users found that the rubber (excluding erasers and shoe soles) often deteriorated quickly and stank. Also, it became gummy in hot weather.

This went on until 1839, when American Charles Goodyear learned how to vulcanize the rubber. He learned that if you add Sulphur to the latex rubber, the polymers will stabilize and the rubber will become durable. He received a patent for the vulcanization process in 1844. Nevertheless, this process wasn’t used much until after 1889, when manufacturers began creating rubber bike tires and rubber automobile tires. By the early 1900s, the demand for rubber around the world had skyrocketed, eventually leading to the development of synthetic rubber compounds. Today, less than half of all rubber materials manufactured worldwide are made from natural rubber.

Brothers Isaiah and John Hyatt patented the first rubber injection molding machine in 1872. Over the course of the rest of the 1800s and the 1900s, others made many improvements on this first molding machine. Also, as chemists came up with new kinds of synthetic rubber, like liquid silicone, engineers were able to come up with new ways of molding. For example, in the 1970s, James Watson Hendry invented the gas-powered injection molding machine, which allowed manufacturers to significantly increase their product output.

From the late 20th and early 21st century, one of the most important contributions to rubber molding has been automation. Today, the rubber industry relies on a mixture of CNC technology and CAD programming to create a high volume of custom mold rubber products.

Rubber Molding Materials Process

The various types of rubber that can be molded include natural rubber, as well as synthetic rubber such as neoprene, foam rubber, EPDM, silicone rubber, and liquid silicone rubber. While synthetic rubbers have the same positive qualities as natural rubber, they display other qualities as well. Synthetic rubbers can be made corrosion-resistant, heat-resistant, ozone resistant, inert with certain chemicals, and made with varying degrees of properties such as rigidity, flexibility, durability, and strength.

Natural Rubber

Natural rubber comes from the sap of certain trees, such as some trees of the genera Ficus. Most often, though, it is extracted from the Pará tree (hevea brasiliensis), more commonly known as the rubber tree. Agricultural workers get it by tapping into the tree, just as you would get maple syrup from a maple tree. Rubber producers then mix the sap with formic acid to get it to coagulate. This uncured rubber substance contains latex. For this reason, it is often passed over by manufacturers looking to avoid causing an allergic reaction.

Neoprene

The first synthetic rubber to be produced on an industrial scale was neoprene. Developed by DuPont in the 1930s, it is a general-purpose chloroprene polymer. Manufacturers use it to mold liners, gaskets and various gardening and household items. Neoprene products are susceptible to degradation at the hands of chemicals like acetic acid, turpentine and iodine.

Foam Rubber

Foam rubber is manufactured with foaming agents that make it flexible and air-filled. It may be made from a number of different rubbers, but most often, it is made from polyurethane. Foam rubber can be twisted, scrunched, stretched, pushed or pulled without detriment. It comes in two main types: open cell and closed cell. Open cell foam rubber products feature interconnected pores, while closed cell foam products feature disconnected pores. Think of it this way: Open cell foam is open to others; therefore, its pores are connected. Closed cell foam is closed off to others, so its pores keep to themselves. Also, because closed cell foam pores are not spread out and connected, more are able to fit into the space, making closed cell foam denser.

Open cell foam rubber is used to make automobile trim, automobile seat padding and padding for pillows and mattresses. It is also used as padding in packaging and for noise control. Closed cell foam rubber is used to make thick auto products, insulation, thermal management products, elbow pads, knee pads, gloves, wetsuits, surgical scrubbers, x-ray positioning pads and orthopedic braces.

EPDM

EPDM, or ethylene propylene diene monomer, is a synthetic rubber with a lot of great qualities. It, for example, has excellent resistance to: steam, ozone, heat and extreme weather. In addition, it provides superior electrical insulation. EPDM is common for use in automotive manufacturing (electrical gaskets and door seals) and building construction (roofing materials). It is also an important component of engine cooling system hoses.

Elastomers

Elastomers are among the most important polymers used in industries for numerous applications. These polymers have elasticity and viscosity; therefore, they are also known as viscoelastic. Silicone rubber is one such elastomer. It is a high-performance rubber that exhibits an unusual blend of properties such as high-temperature resistance and flexibility.

Silicone Rubber

Silicone rubber is a synthetic rubber made up of silicon, oxygen, carbon and hydrogen. It comes in both liquid and solid form. Solid silicone rubber is quite easy to sanitize, making it popular in the food processing, medical and biotech industries. Its structure always consists of an organic moiety coupled to the silicon and a siloxane backbone (silicon-oxygen chain). Both forms are high temperature resistant and remain stable when exposed to temperatures up to 446℉. Because of its heat stability, silicone rubber is popular for use in metal casting. Silicone rubber, however, has poor fuel and mineral oil resistance. For applications involving those substances, fluorosilicone rubber is a good substitute.

Silicone rubber is a very sticky gel or liquid when it is uncured. It must be cured, vulcanized, or catalyzed to become a solid. At the time of manufacturing, this is often done in two stages to create the desired exact shape, followed by a lengthy post-cure phase. It can also be used in injection molding.

Silicone rubber, used throughout industries and homes, is a part of our daily life. It is a stretchy material that is used to make muffin pans, pot holders, food molds, medical devices, jewelry components, and much more. Silicone molds are made from RTV (Room Temperature Vulcanizing) silicone by a combination of parts that results in a chemical reaction, causing the rubber to vulcanize into a non-stick, stretchy, and durable material. Silicone rubber is of many types to be made into different molds for different purposes.

Properties of Silicone Rubber Molds

- Silicone molds are heat resistant and can be used at 302 °F (150 °C) degrees without any change in performance. They have excellent thermal and thermo-oxidative resistance and a wide operating temperature range.

- They are also cold-resistant and can retain elasticity even at -76 °F (-60 °C) to -94 °F (-70 °C). They are flexible at lower temperatures due to their low glass transition temperature.

- Silicone rubber is flammable, but if a flame retardant is added, it becomes flame retardant and self-extinguishing.

- Silicone rubber is highly resistant to any electric discharge and remains stable even at high temperatures and frequencies.

- Other unique properties include being hydrophobic and having the ability to release materials from their surface easily.

- Exceptional defense against oxygen, ozone, and sunlight.

- Ability to easily withstand electromagnetic and particle radiation (UV, alpha, beta, and gamma rays).

- Outstanding non-stick and non-adhesive qualities.

- Less toxicity.

- Transparency in optics.

- Excellent insulating characteristics.

- Low reactivity.

- Superb biocompatibility.

- Superior mechanical qualities.

How is Silicone Rubber made?

- The silicon atoms in the silicon dioxide compound, silica, must be separated to create silicone.

- To do this, enormous amounts of quartz sand are heated to extremely high temperatures, frequently up to 1800 °C.

- After this, the silicone is heated and mixed with methyl chloride in multiple steps. The resulting polymerized siloxane, known as polydimethylsiloxane, is then distilled. The polymerization of polydimethylsiloxane is therefore possible.

- Many techniques are used to accomplish this, depending on the intended application of the finished product. The catalyst is mixed with required additives, including colors and the raw silicone compound.

- Afterward, it is either extruded or injection molded. The final step in the manufacturing process is curing.

Applications of Silicone Rubber

Following are some of the industrial applications of silicone rubber:

- Aerospace – space suit elements

- Automotive – gaskets and seals

- Construction – coatings and sealants

- Electrical and electronics – adhesives and encapsulants

- Food processing – food molds

- Medical – medical instrument components such as seals, tubes, and valves

- Recreation – goggles and mouthpieces

Rubber Molding Process Details

1. Map out details of product to be molded (material, dimensions, shape, thickness, etc.)

2. Design the die or mold cavity you will use to shape the raw rubber, known as stock.

3. Collect the stock.

4. Deposit the stock into whatever machine you use.

5. Allow to cool and harden.

6. Eject the rubber shape.

7. Finish as needed.

Once removed, the mold could have certain imperfections such as seams. If this is the case, the rubber product may have to undergo further processing if necessary. It is possible to add a variety of finishes and textures to the final product to add an aesthetic touch.

Rubber Molding Design

When preparing to mold a part, manufacturers first think about how the product should look, what qualities it must have and its dimensions. By considering these, they can pick a rubber material with which to work, then turn to their computer programming to create a precise design.

Custom rubber molding, especially, custom rubber injection molding, is a very popular choice with customers because, while it is more costly than standard molding, custom molding is still less expensive than alternative rubber manufacturing methods. Custom mold design offers the possibility of shapes, finishes, textures, tolerances and dimensions made unique just for your application.

Rubber Molding Variations and Similar Processes

The types of rubber molding include injection molding, liquid injection molding, insert molding, compression molding, transfer molding and blow molding. All six methods have their similarities; however, injection molding is used more widely than any other method. An alternative method to rubber molding in general is rubber extrusion.

Injection Molding

The first step in the injection molding process involves collecting raw rubber material, known as stock. The stock is then placed into a hopper that is suspended over a conveyance channel. The stock is then released, and processed through a channel that features a large turning screw. By the time the stock reaches the end of the channel, it is completely melted as a result of a combination of the heating elements within the channel, and the friction caused by the screw’s motion. At the end of the channel is a mold cavity into which the molten rubber is injected. The elements of heat and pressure work together to ensure that the molten rubber fills the cavity entirely, down to the very contours of the mold, and is uniformly distributed. The molten rubber is allowed to cool and harden within the mold, and can be safely removed from the mold cavity once it reaches a solid state.

- It is the most common, robust, and complex process because the products vary in size and application.

- Material is injected into mold halves with a plunger.

- This method is best because it has great output production, can be automated, and has short molding cycles.

- Many types of materials can be used at the same time, and no trimming of product is needed.

- Trapped air bubbles, flash, and sinks are problems that can be solved by venting.

- It is best for thin-walled products; therefore, it is used to make small parts and automobile body panels.

Liquid Injection Molding

Liquid injection molding is quite similar to regular injection molding. The difference is mainly that manufacturers use liquid stock as the starting raw material. In addition, the machinery used includes a metered pump that helps regulate and control stock flow. The pump discharges the liquid, which manufacturers then mix with any additives. Once mixed, a nozzle injects the mixed liquid into a shaped mold. The manufacturers then close the mold tightly with clamps and apply the appropriate amount of heat and pressure for creating the product. By liquid injection molding rubber, manufacturers can produce products more quickly, since they do not have to liquify the stock. Also, liquid injection molded products require very little finishing.

- Liquid injection molding creates products in cavities, and the liquid material is injected into these cavities.

- In this process, raw materials are mixed mechanically. After the product is hardened, it is ejected from the mold cavity.

- It is a high-pressure process, has a shorter cure time, and is used to make intricate designs with great precision.

- This method is used to mass-produce products, with thermal imaging technology employed to identify any errors.

- It is best to make gaskets, o-rings, keypads, and electronic contacts.

Insert Molding

Insert molding is a type of rubber and plastic injection molding. During insert molding, manufacturers mold or form rubber parts around non-rubber parts, called inserts. Common insert products include knife blades and surgical tubes.

Compression Molding

Compression molded parts are made when the manufacturer pre-weigh, pre-measure and preheats the stock, and then inserts it into a pre-shaped mold cavity. After that, they close the mold, compressing and squeezing the stock until it stretches into it takes on the shape of the mold. Then, they allow it to harden and cool before removing it. The compression molding process is often followed up by secondary processing for the removal of excess material (flash). Through rubber compression molding, manufacturers can make large, intricate products quite inexpensively. However, the results are not always consistent.

- Preform rubber is placed into heated cavities to create molds.

- The raw material can be in the form of pre-measured pellets, granules, or powder.

- The cavities are closed by heated plungers and put under pressure of 15,000psi to 20,000psi.

- It is an economical method that has a low-to-medium production rate.

- The cavities should be cleaned properly to avoid any contamination.

- Seals, o-rings, gaskets, automotive parts, and cushioning pads are products made from this process.

Transfer Molding

Like compression molding, during transfer molding, manufacturers take a pre-weighed and pre-measured rubber stock, or “preform” and insert it into a cavity above the mold, called a “pot.” Once the stock is placed, they press a heavy mechanical ram into it while applying heat. This forces the preform into the mold via a runner and gate system, where it melts. Manufacturers keep the ram in place until the preform takes on the shape of the mold in its entirety. Transfer molding is valued because it allows manufacturers to not only produce precision molded rubber products, but also rubber products bonded to metal surfaces.

- A plunger puts the material in the heated cavity, and then it is cooled down to take the shape of the mold.

- The waste created by compression of the mold is then manually trimmed, followed by cryogenic processes, tumbling, or precision grinding.

- It has a shorter production cycle and a tighter dimensional tolerance.

- This process is used to make smaller, more complex, and more detailed parts.

Blow Molding

Rubber blow molding is a molding process by which hollow rubber products are formed. It involves the use of a parison (tube-like plastic shape with a hole in one end) or preform. To expand the part, manufacturers clamp the parison to a mold and then blow compressed air into the parison hole. As the rubber expands, it touches the mold and takes on its shape. After it cools and hardens, manufacturers open the mold and eject the newly formed part.

Liquid Silicone Rubber (LSR)

Liquid silicone rubber is a low viscosity, high purity thermoset elastomer that maintains its mechanical qualities throughout a wide temperature range, i.e., from -50 °C to 250 °C. This heat-cured elastomer is a great option if you want outstanding optical clarity and long-term endurance in a demanding environment (with high temperatures, UV exposure, etc.).

Injection molding is the only method used to produce liquid silicone rubber, which is heat-cured while it is being molded. The primary benefit of LSR is the potential to combine several pieces into one, which allows for significant cost savings. In addition, liquid silicone rubber can lead to significantly increased production by using smaller equipment and eliminating material waste.

Rubber Extrusion

Rubber parts can alternatively be produced through rubber extrusion. However, extruding machines have much more limited capabilities. An extruder only has control over the X and Y axes, and are thus much more suited for the production of simpler rubber products such as rubber baseboards or rubber sheets. Rubber molding allows from design control over three axes due to the process involving a molding cavity instead of a die.

Extrusion of Raw Material

- Extrusion is done by creating uncured raw material with the help of dye to form a uniform cross-sectional-shaped product.

- The raw material is passed through the extruder, which uses screws for temperature fluctuation and rotation.

- After shaping the product into the required shape, it is washed and cooled by air or water and then cut into the final product.

- The extrusion process is low-cost, takes less time, and produces a bulk of products.

- It is difficult to maintain tolerance criteria, and per-part price varies due to the complexity of the dye.

- It is best for the production of gaskets, tubing, and seals.

Product Calendering

- It is a speedy, continuous sheeting process that uses a number of rollers to press the semi-liquid material into a hard sheet.

- The products are then coated onto fabrics.

- It is essential to set an optimum temperature for rollers to avoid overheating and sticking.

- Creeping of the product is also a concern in calendering.

- It is used to make dye sheet cuts and thin sheets of material.

Benefits of Rubber Molding

Rubber molding offers quite a few benefits, especially when compared to other rubber forming techniques. First, rubber molding offers versatility. This is because rubber molding manufacturers can make use of so many different types of rubber-based raw materials, and also because they can produce a wide range of complex custom parts. Second, rubber molding is efficient and reduces production time. It is also well-paired with large volume runs.

Choosing a Rubber Molding Manufacturer

When selecting a rubber molding service provider, you need consider the following: What’s my application? What qualities must my molded product have (tensile strength, corrosion resistance, flexibility, temperature resistance, etc.)? Do I need to adhere to any industry/regional standard requirements? How much customization do I require? How many items do I need? What’s my budget? What’s my timeline?

By knowing the answers to these questions, you can 1) know what product and service offerings to look for when researching, and 2) have a more productive conversation with your prospective manufacturers. We know that there are a lot of manufacturers and suppliers floating around out there, some of dubious quality. So, to help you wade through the muck, we’ve provided on this page a comprehensive list of experienced, quality manufacturers you can trust. To learn more about each of them, check out the profiles we’ve provided. Try to choose three or four in whom you’re most interested, and then reach out to each of them with your specifications. Have those production conversations we talked about, and when you’re done, compare and contrast their answers. From among them, choose the one you feel can offer you services (including customer services) best aligned with your interests. Call them again, and get started!

Check out our Polyurethane Molding website

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services